JUFENG Precision Aluminum Die Casting Components for Telecom Applications

Precision-Engineered Telecom Solutions

JUFENG Precision designs and manufactures superior aluminum die casting components that meet stringent international protection standards for the telecommunications industry. Our high-performance castings are engineered for reliability in both industrial and commercial telecom applications, ensuring optimal performance in demanding environments.

Advantages of JUFENG’s Telecom Die Castings

Our aluminum die casting solutions provide exceptional protection for sensitive electrical and electronic components, offering:

- Robust Durability – Withstands extreme temperatures, vibrations, and mechanical stress

- Supeior Corrosion Resistance – Aluminum alloys provide long-term protection against rust and degradation

- Precision Engineering – Complex geometries with tight tolerances for seamless integration

- Environmental Resistance – Waterproof (IP67+) and dustproof designs for harsh outdoor conditions

- Lightweight & Strong – High strength-to-weight ratio for easy installation without compromising durability

Built for Harsh Environments

JUFENG’s die casting production process ensures telecom components that excel in challenging conditions, including:

- Extreme weather exposure (UV, rain, snow)

- Dusty or corrosive industrial settings

- High-humidity and wet environments

- Long-term outdoor deployment

Our components outperform alternative materials with superior longevity, reduced maintenance, and reliable performance—making JUFENG Precision the trusted choice for mission-critical telecom infrastructure worldwide.

Explore our full range of telecom die casting solutions designed for durability, precision, and compliance with global standards.

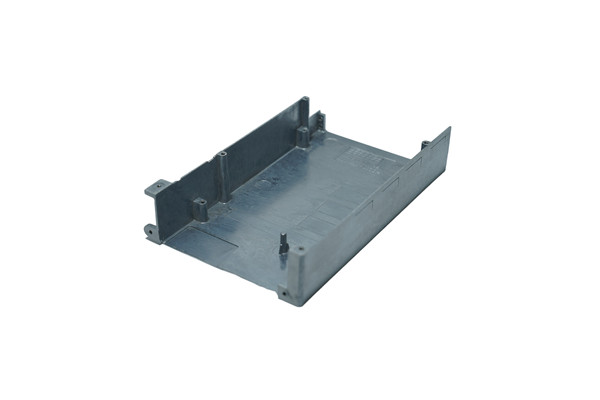

JUFENG Precision Aluminum Die Casting Manufacturing Capabilities

JUFENG Precision specializes in producing high-performance aluminum die-casting components tailored to precise telecommunications industry specifications. Our standard telecommunications castings can be fully customized to meet specific customer design requirements, including precision machined mounting holes for effortless installation. These components are made of high-quality aluminum alloy using advanced high-pressure die-casting technology, with excellent structural integrity and durability.

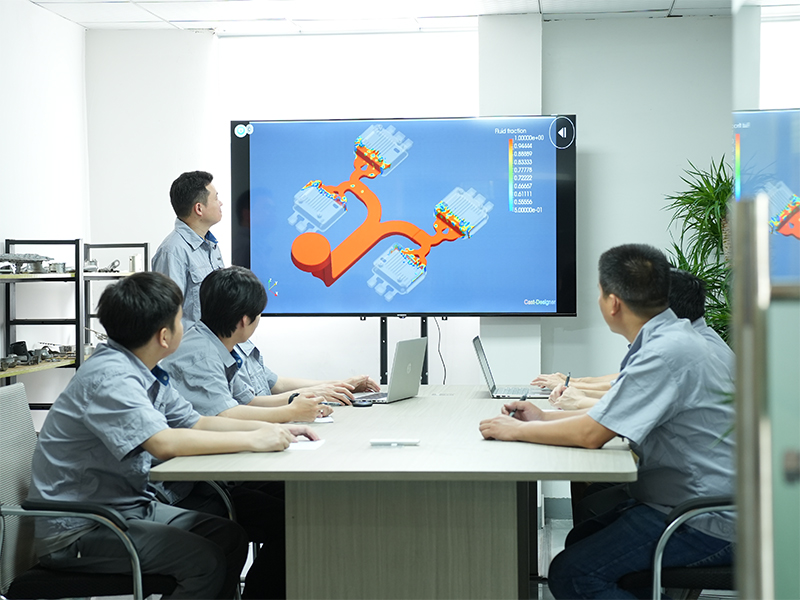

DFM review meeting

Material quality control

Die casting process

CNC machining process

Surface finishing process

Dimension inspection

Advanced Equipment for Aluminum Die Casting

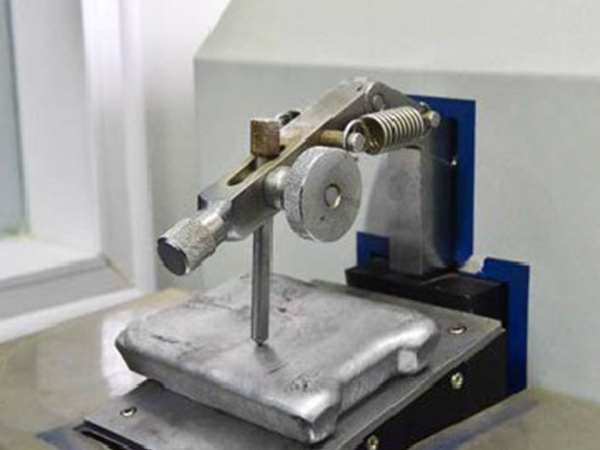

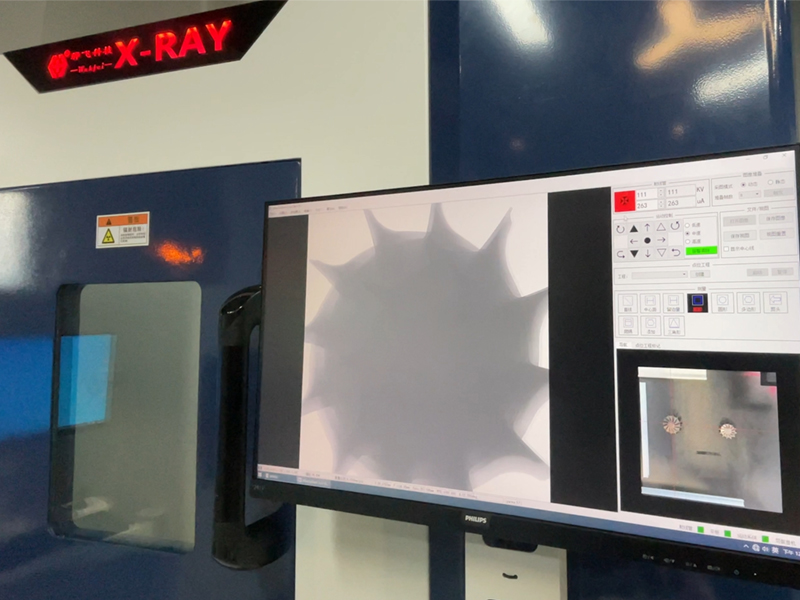

X-ray instrument

Die casting machine

Die casting inspection

Mecanizado CNC

Laser etching machine

CMM equipment

Recent Telecom Aluminum Die Casting Projects

Part Name:

Material:

Size:

Weight:

Machine Tonnage:

Surface Finish:

Production Process:

Applied Industry:

Telecommunication Die Casting FAQ Guide

Continue reading our FAQ guide to learn how die casting solutions can address your specific telecommunications component challenges.

What Are the Benefits of Die Casting for Telecommunication Components?

In the fast-evolving telecommunications industry, manufacturers demand precision-engineered components that combine durability with complex functionality. JUFENG’s aluminum die casting solutions provide the ideal manufacturing process for telecom applications, offering these key advantages:

Superior Engineering Capabilities

- Complex geometry production: Die casting enables intricate shapes and fine details that would be costly or impossible with other manufacturing methods

- Thin-wall technology: Achieve lightweight yet strong components with walls as thin as 0.5mm, perfect for compact telecom devices

- Minimal draft angles: Allows for superior dimensional accuracy on internal features and components

Uncompromising Quality & Performance

- Exceptional consistency: Maintains identical quality across high-volume production runs (10,000+ units)

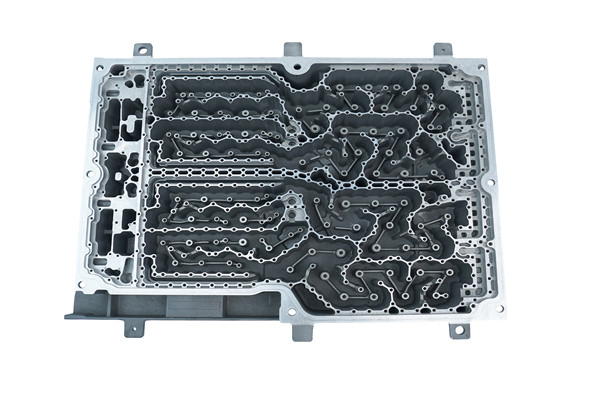

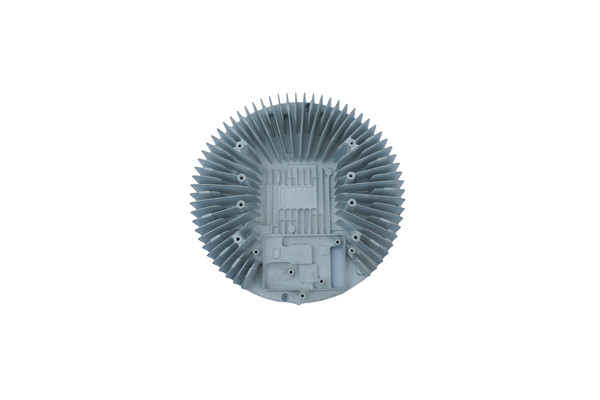

- Integrated thermal management: Heat sinks can be cast directly into components for optimal thermal performance

- Robust housings: Die cast aluminum provides superior EMI/RFI shielding and impact resistance

Enhanced Manufacturing Efficiency

- Reduced secondary operations: Near-net-shape casting minimizes post-processing requirements

- Versatile finishing options: Choose from multiple surface treatments including:

- Anodizing (Type II/III)

- Powder coating

- E-coating

- Chemical film conversion

Material Advantages

- High strength-to-weight ratio: Aluminum alloys (A380, A383) provide durability without excessive weight

- Corrosion resistance: Ideal for both indoor and outdoor telecom equipment

- Excellent conductivity: Supports optimal electrical and thermal performance

JUFENG’s telecom die casting solutions are trusted by leading global manufacturers for 5G infrastructure, base stations, antenna housings, and fiber optic components. Our ISO 9001 and IATF 16949 certified processes ensure every component meets the stringent requirements of modern telecommunications applications.

Discover how our die casting expertise can optimize your telecom component design – request a consultation today.

What Are the Ideal Die Casting Types for the Telecommunications Industry?

In the telecommunications sector where precision and reliability are paramount, JUFENG offers specialized die casting solutions tailored for telecom components. Our advanced processes deliver superior results based on material properties, part dimensions, and geometric complexity.

Primary Die Casting Methods for Telecom Applications

- Hot-Chamber Die Casting

Best for: Zinc, magnesium, and copper alloys

Telecom advantages:

- Rapid cycle times for high-volume production

- Excellent for small-to-medium precision components

- Ideal for RF shielding enclosures and connector housings

- Cold-Chamber Die Casting

Best for: Aluminum alloys (A380, A383)

Telecom benefits:

- Handles larger components like antenna bases

- Suitable for heat-sensitive 5G equipment

- Corrosion-resistant for outdoor applications

Specialized Die Casting Variations for Telecom

Process | Key Features | Telecom Applications |

Vacuum Die Casting | Reduces porosity by 90% | High-strength structural components |

Semi-Solid (SSM) | 40-60% solid content for dense castings | EMI-sensitive enclosures |

Low Pressure | Excellent surface finish | Waveguide components |

High Pressure | Tight tolerances (±0.05mm) | Heat sink integrated housings |

Squeeze Casting | Near-zero porosity | Mission-critical infrastructure |

Why JUFENG’s Solutions Excel for Telecom

- Material expertise: Specialized alloys for optimal signal transmission

- Thin-wall capability: Down to 0.5mm for lightweight designs

- Surface treatments: Anodizing, powder coating, and EMI shielding options

- Quality assurance: IATF 16949 certified for automotive-grade reliability

Our engineers work closely with telecom clients to select the optimal casting method for each application, balancing performance requirements with cost efficiency. From 5G base stations to fiber optic connectors, JUFENG delivers precision-cast components that meet the stringent demands of modern telecommunications.

Contact our technical team to discuss the best die casting solution for your specific telecom component needs.

What Is the Difference Between Telecommunication Casting and Injection Molding?

In manufacturing components for the telecommunications industry, JUFENG offers both die casting and injection molding solutions – each with distinct advantages depending on application requirements. Here’s a detailed comparison:

Fundamental Differences

Characteristic | Telecommunication Die Casting | Injection Molding |

Material | Metals (Aluminum, Zinc, Magnesium) | Plastics/Polymers |

Process Temp | 600-700°C (Aluminum) | 200-300°C (Thermoplastics) |

Tooling Cost | Higher initial investment | Lower initial cost |

Production Rate | 100-500 shots/hour | 50-300 shots/hour |

Part Strength | Superior structural integrity | Adequate for non-structural parts |

Process Comparison

While both techniques share similar basic steps:

- Mold/die creation

- Material liquefaction

- High-pressure injection

- Cooling and ejection

Key distinctions emerge in:

- Material properties: Die casting uses metallic alloys with higher thermal/electrical conductivity

- Precision: Die casting achieves tighter tolerances (±0.05mm vs ±0.1mm)

- Surface finish: As-cast metal surfaces often require less post-processing

Advantages of Die Casting for Telecom Applications

- Superior Technical Performance

- EMI/RFI shielding: Essential for 5G and RF components

- Heat dissipation: Integrated heat sinks in single-piece designs

- Structural durability: Withstands harsh outdoor environments

- Manufacturing Efficiency

- Near-net-shape production: Reduces secondary machining

- Thin-wall capability: As thin as 0.5mm for lightweight designs

- High-volume consistency: Maintains precision across 100,000+ cycles

- Long-Term Value

- Tooling longevity: Steel dies last 100,000+ shots

- Material recyclability: Aluminum scrap can be 95% recycled

- Total cost advantage: Lower per-part cost at high volumes

When to Choose Each Process

JUFENG recommends die casting for:

- Metal enclosures requiring EMI shielding

- Components with integrated thermal management

- High-stress structural parts

Injection molding suits:

- Non-conductive plastic housings

- Low-volume prototype runs

- Cost-sensitive consumer devices

Our engineering team can help determine the optimal manufacturing method for your specific telecom component requirements, balancing performance needs with production economics.

What Can Be Made from Telecommunication Die Casting?

At JUFENG, we specialize in high-precision die casting solutions for the telecommunications industry. Our advanced manufacturing capabilities enable us to produce mission-critical components that meet the stringent demands of modern communication systems.

Key Telecommunications Components Produced Through Die Casting

- Fiber Optic Network Components

- Precision connectors and adapters with micron-level tolerances

- Optical transceiver housings that maintain signal integrity

- Fiber alignment components with exceptional dimensional stability

- Durable enclosures resistant to environmental stressors

- 5G & Wireless Infrastructure

- Antenna housings with integrated EMI shielding

- RF filter boxes for signal purity

- Base station components that withstand outdoor conditions

- Waveguide components with precise internal geometries

- Networking Equipment

- High-density connector housings

- Switch chassis with optimal thermal management

- Server rack components combining strength and lightness

- Zinc alloy contact pins for reliable electrical connections

Advantages of JUFENG’s Telecom Die Casting

Superior Material Properties:

- Aluminum alloys (A380, A383) for lightweight durability

- Zinc alloys for precision electrical contacts

- Magnesium alloys for RF-sensitive applications

Advanced Manufacturing Capabilities:

- Thin-wall casting down to 0.5mm

- Complex internal features without secondary machining

- Integrated heat dissipation solutions

- Tight tolerances (±0.05mm) for optical alignment

Quality Assurance:

- 100% dimensional inspection

- Porosity testing for pressure-tight components

- Surface finish options from as-cast to precision machined

Why Choose JUFENG for Your Telecom Components?

- Industry-Specific Expertise: Decades of experience serving telecom leaders

- Complete Solutions: From design assistance to final finishing

- Scalable Production: Prototype to high-volume manufacturing

- Material Science Leadership: Custom alloy development for specific applications

Whether you’re developing next-generation 5G infrastructure, fiber optic networks, or satellite communication systems, JUFENG has the die casting expertise to bring your designs to life with uncompromising quality and reliability.

Contact our engineering team today to discuss your specific telecom component requirements.

Surface Treatment Solutions for Telecommunications Die Cast Components

At JUFENG, we offer a comprehensive range of surface treatments specifically engineered to enhance the performance and durability of telecom die cast parts. Our finishing processes are tailored to meet the unique demands of 5G infrastructure, fiber optic equipment, and wireless communication systems.

Advanced Surface Treatment Options

- Protective Coatings

Anodizing (Type II & III)

- Creates corrosion-resistant surface

- Improves dielectric strength for RF components

- Available in multiple colors for part identification

Powder Coating

- Superior weather resistance for outdoor applications

- Thicker protective layer than wet paint

- Special formulations for EMI shielding

E-Coating (Electrophoretic Deposition)

- Uniform coverage on complex geometries

- Excellent base for secondary finishes

- RoHS-compliant formulations available

- Functional Finishes

Chromate Conversion Coating

- Enhances corrosion protection

- Maintains electrical conductivity

- Ideal for connector components

Electroless Nickel Plating

- Uniform deposition without power lines

- Improves wear resistance

- Suitable for high-frequency contacts

- Aesthetic & Identification Treatments

Laser Marking

- Permanent part identification

- No material removal or surface damage

- Compatible with most coatings

Silk Screening

- High-resolution graphics

- Durable logos and indicators

- Chemical-resistant inks available

What Materials Are Used to Make Telecommunication Parts?

At JUFENG, we specialize in high-performance die casting materials specifically engineered for telecommunications applications. Our material selection is based on rigorous testing and industry experience to ensure optimal performance in demanding telecom environments.

Primary Die Casting Materials for Telecom Components

- Aluminum Alloys (A380, A383, ADC12)

Key Advantages:

- Lightweight (2.7 g/cm³ density) for portable devices

- Excellent EMI/RFI shielding capabilities

- Superior thermal conductivity (90-120 W/m·K)

- Corrosion resistant for outdoor applications

- Cost-effective for high-volume production

Typical Applications:

- 5G antenna housings

- Fiber optic connector bodies

- Base station heat sinks

- RF shielding enclosures

- Zinc Alloys (ZA-8, ZA-12, ZA-27)

Key Advantages:

- High dimensional stability (±0.1% shrinkage)

- Excellent electromagnetic shielding

- Superior surface finish for plating

- Good vibration damping properties

Typical Applications:

- Precision connectors

- Small signal components

- Wear-resistant contact parts

- Magnesium Alloys (AZ91D, AM60B)

Key Advantages:

- Lightest structural metal (1.8 g/cm³)

- Good strength-to-weight ratio

- Excellent EMI shielding effectiveness

- Damping capacity 100x greater than aluminum

Typical Applications:

- Portable device housings

- Satellite communication components

- Vibration-sensitive instruments

Specialized Telecom Alloys

Material | Key Properties | Telecom Applications |

Copper Alloys | Highest conductivity (385 W/m·K) | High-frequency components |

Silicon Tombac | Steel-like strength, castability | Structural brackets, mounts |

Lead-Free Tin | Solder compatibility, corrosion proof | Sealing components, gaskets |

Material Selection Considerations

JUFENG’s material experts evaluate:

- Electrical Requirements: Conductivity vs shielding needs

- Thermal Management: Heat dissipation characteristics

- Mechanical Demands: Strength, stiffness, and fatigue resistance

- Environmental Factors: Corrosion resistance, UV stability

- Cost Efficiency: Material vs processing trade-offs

Our engineering team can recommend the optimal alloy based on your specific:

- Signal frequency requirements

- Weight constraints

- Environmental exposure

- Budget considerations

- Regulatory compliance needs

Contact JUFENG today to discuss the best material solution for your telecom component application.

Why Aluminum Alloys Are Ideal for Telecommunications?

Aluminum die-cast components offer several advantages that make them particularly suitable for telecom applications:

- Lightweight– Reduces overall equipment weight without compromising strength

- High Strength & Hardness– Ensures durability in demanding environments

- Thermal Stability– Withstands high operating temperatures

- Corrosion Resistance– Prolongs component lifespan in various conditions

- Excellent Electrical Conductivity– Enhances signal transmission efficiency

- Superior EMI/RFI Shielding– Critical for preventing electromagnetic interference in telecom devices

- Versatile Finishing Options– Allows for aesthetic and functional surface treatments

- Recyclability– Supports sustainable manufacturing practices

- High Strength-to-Weight Ratio– Balances structural integrity with lightweight design

Top Aluminum Alloys for Telecommunications Die Casting

Several aluminum alloys stand out for telecom applications due to their specialized properties:

- A380– The most widely used alloy, offering excellent castability, mechanical strength, and thermal performance.

- 383 (ADC12)– An ideal alternative to A380, particularly for intricate and thin-walled components.

- A413– Known for superior pressure tightness, making it suitable for sealed telecom enclosures.

- B390– Provides exceptional hardness and wear resistance, ideal for high-stress components.

- A360– Offers excellent fluidity and pressure tightness for complex geometries.

- K-Alloy– A specialized cold-chamber die-casting alloy designed for extreme operating conditions.

Additional Alloys for Telecom Applications

Beyond aluminum, other alloys used in telecommunications die casting include:

- Silicon Tombac– For specialized shielding applications

- ZAMAK (Zinc-Aluminum)– Balances strength and cost-effectiveness

- AZ91D Magnesium– Ultra-lightweight with good EMI shielding properties

At JUFENG, we specialize in high-performance die-cast components for the telecom industry, frequently utilizing alloys such as ADC12, A380, and ADC10 to meet stringent quality and performance requirements.

By selecting the optimal alloy, telecom manufacturers can ensure reliability, signal integrity, and long-term durability in their products.

What Telecommunication Parts Can Be Made With Die-Casting?

Die-casting is a highly versatile manufacturing process that produces precision metal components for the telecommunications industry. This method is ideal for creating complex, high-performance parts that require excellent conductivity, durability, and electromagnetic shielding. At JUFENG, we specialize in die-cast telecom components using high-quality alloys such as aluminum, zinc, and magnesium.

Key Telecommunication Parts Made Through Die-Casting

Die-casting enables the production of a wide range of critical telecom components, including:

- 5G & Wireless Communication Housings – Durable enclosures for routers, modems, and small cells

- RF (Radio Frequency) Components – Shielding casings, antenna mounts, and waveguide parts

- Bluetooth & IoT Device Housings – Lightweight, interference-resistant enclosures for smart devices

- Satellite Communication Parts – High-strength structural components for satellite systems

- Network Switching Equipment – Heat-resistant chassis and brackets for servers and switches

-GPS & Navigation System Components – Precision parts with excellent dimensional stability

- Voice Command Device Frames – Aesthetically refined yet functional housings for smart speakers

- Optical Fiber Connectors & Adapters – Corrosion-resistant, high-precision fittings

- Telecom Base Station Components – Structural parts with superior EMI shielding

Why Choose Die-Casting for Telecom Components?

Die-casting offers unmatched advantages for telecommunications applications:

✔ High Precision – Tight tolerances for seamless assembly

✔ Superior EMI/RFI Shielding – Critical for signal integrity

✔ Lightweight & Durable – Ideal for portable and fixed telecom devices

✔ Cost-Effective Mass Production – Consistent quality for high-volume orders

At JUFENG, we leverage advanced die-casting techniques to manufacture telecom components that meet stringent industry standards. Our expertise in materials like ADC12, A380, and magnesium alloys ensures optimal performance for next-generation communication technologies.

Whether you need RF enclosures, 5G infrastructure components, or IoT device housings, die-casting provides the perfect solution for high-performance telecom applications.

What Is the Process of Making Die Casting Parts From Design to Packaging?

When you partner with JUFENG for your die casting needs, you can expect a comprehensive manufacturing process that transforms your initial concept into high-quality finished products. Our professional die casting services cover every stage from engineering design to final packaging, ensuring precision and consistency throughout production.

The Complete Die Casting Manufacturing Process

At JUFENG, we follow a meticulous 4-stage production process to deliver superior die cast components:

- Mold Design and Die Manufacturing

- Our engineers analyze your drawings and specifications

- CAD/CAM software is used to design optimal mold configurations

- High-grade steel molds are precision-machined for durability

- Mold flow analysis ensures proper material distribution

- Precision Die Casting Production

- Molten metal is injected into molds under high pressure

- We utilize both high pressure cold-chamber casting methods

- Process parameters are carefully controlled for consistency

- Automated systems ensure repeatable quality

- Surface Finishing Treatments

- Deburring to remove sharp edges and imperfections

- Vibratory finishing for smooth surface texture

- Custom finishing options including:

Powder coating

-Anodizing

-Plating

-Painting

-Laser etching

- Quality Inspection and Packaging

- Dimensional verification with CMM and other metrology tools

- Mechanical property testing

- Visual inspection for surface defects

- Custom packaging solutions for protection during shipping

- Final quality certification before shipment

Additional Value-Added Services

JUFENG offers comprehensive secondary operations to meet your specific requirements:

- Precision CNC machining

- Heat treatment (annealing, tempering)

- Sub-assembly and full product assembly

- Custom labeling and branding

- Inventory management and JIT delivery

Our streamlined process from design to delivery ensures you receive high-quality die cast parts that meet your exact specifications, delivered on time and at competitive prices. With JUFENG as your manufacturing partner, you can be confident in every stage of the production process.