Precision Die Casting for Medical Devices | JUFENG Precision

Medical device manufacturing demands exceptional precision, stringent quality standards, and reliable low-to-medium volume production capabilities—a challenge many aluminum die casting suppliers struggle to meet. At JUFENG Precision, we specialize in high-performance die-cast components for the medical industry, ensuring superior functionality, flawless surface finishes, and strict compliance with industry regulations.

Our Proven Process for Your Medical Project Success:

- Requirement Consultation

Share your project details—component specifications, material preferences, regulatory standards, and logistical needs. - Design Review & Engineering Feedback

Our team analyzes your design for manufacturability (DFM), offering optimized solutions for structural integrity, dimensional accuracy, and cost efficiency. - Customized Proposal

Receive a tailored business proposal covering tooling, production timelines, quality control protocols, and value-added services. - Precision Tooling & Production

High-grade mold fabrication (6–15 weeks, project-dependent) followed by rigorous sampling and full-scale manufacturing with zero-defect targets.

Partner with a supplier that meets the critical demands of medical device manufacturing. Contact us to discuss your project today.

One-Stop Die Casting Manufacturing Capabilities

We offer one-stop solutions for mold design & making, die casting, CNC machining, and surface finishing.

High precision, high mix, low-medium volume production.

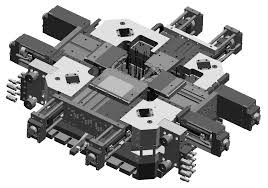

Advanced machines and equipment meet your high-quality requirements

Mold design

Fabrication de moules

Fabrication de pièces moulées sous pression

Precision machining process

Passivation process

Painting process

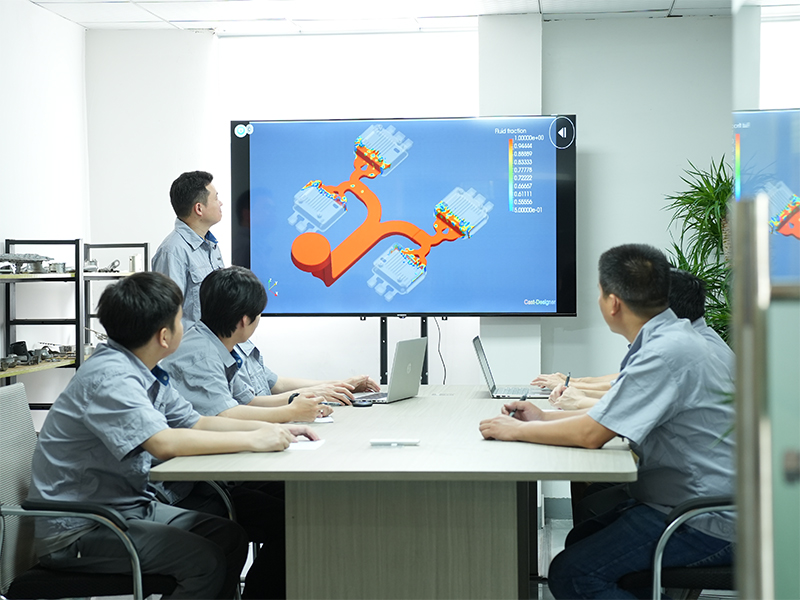

Engineering Support & QA Capability

DFM review

Feasibility analysis

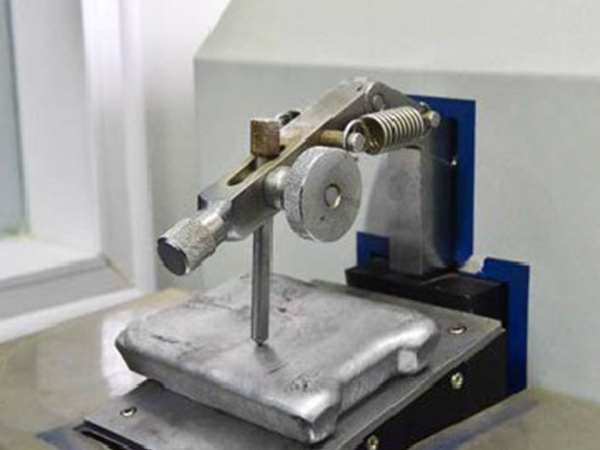

Material analysis

Quality control

CMM

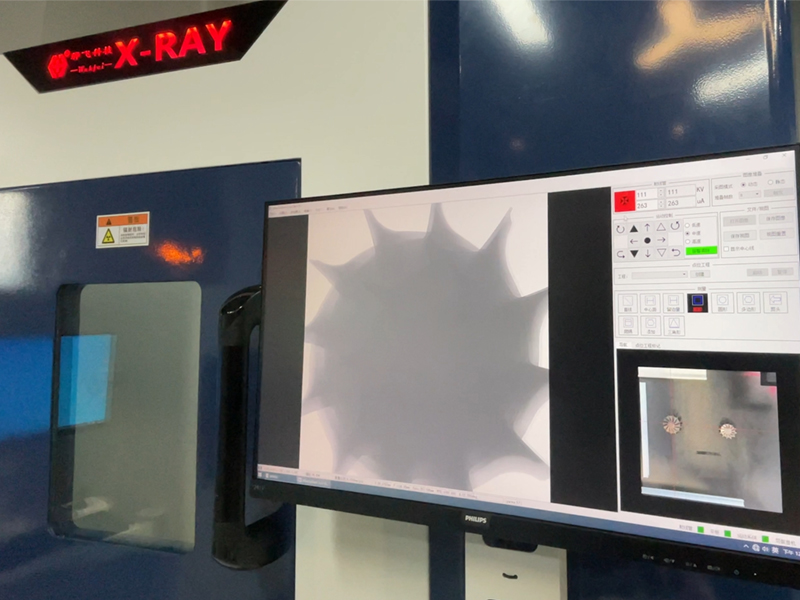

X-ray detector

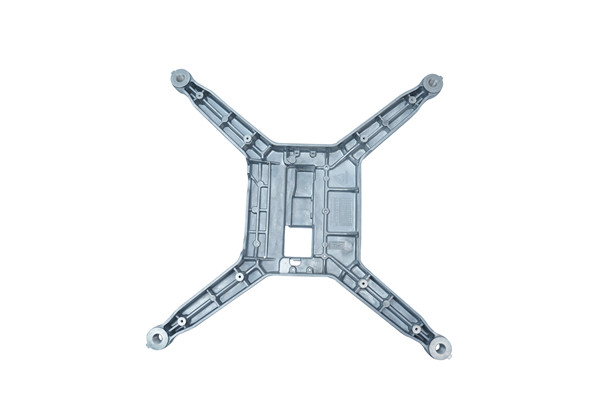

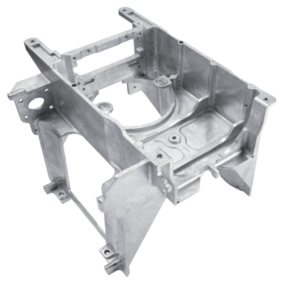

Recent Medical Aluminum Die Casting Projects

Part Name:

Material:

Size:

Weight:

Machine Tonnage:

Surface Finish:

Production Process:

Applied Industry:

MEDICAL DIE CASTING FAQ GUIDE

Precision die casting delivers high-performance medical parts with

exceptional dimensional accuracy, superior strength-to-weight ratios, complex geometries in single-piece constructions.

Aluminum alloys offer distinct advantages:

✔ Cost efficiency: High production yields reduce per-part costs

✔ Performance: Excellent corrosion resistance & EMI shielding

✔ Lightweight: 60% weight reduction vs. steel alternatives

✔ Rapid ROI: Faster cycle times and simplified post-processing

Why Choose Precision Die Casting for Medical Applications?

Medical die casting produces mission-critical components for healthcare technology, including:

Life-saving equipment (defibrillators, patient monitors)

Surgical instruments and handheld devices

Diagnostic imaging system components

Portable medical electronics

These applications demand:

✓ Micron-level precision (typically ±0.05mm tolerance)

✓ Complex geometries with thin walls

✓ Flawless surface finishes (Ra <0.8μm standard)

✓ Strict compliance with medical standards (ISO 13485, FDA)

Why Die Casting Dominates Medical Manufacturing:

- Superior Quality – Produces durable, high-integrity parts

- Design Flexibility – Accommodates intricate shapes and features

- Cost Efficiency – Ideal for medium-volume production

- Material Advantages – Aluminum alloys offer optimal strength-to-weight ratios

As a trusted medical die casting partner, we help manufacturers transform innovative designs into reliable, high-performance medical devices.

Seeking Precision Engineering & Design Excellence in Medical Die Casting?

Producing high-performance die cast medical components—including pacemaker housings, CT scanner parts, diagnostic monitoring systems, and ultrasonic device assemblies—demands advanced engineering expertise and meticulous design. At JUFENG Precision, we specialize in delivering ultra-precise die cast solutions tailored to stringent medical industry requirements.

Our integrated approach combines:

- Rapid Prototyping for accelerated development

- Precision Mold Design & Fabrication for flawless production

- Optimized Die Casting Processes for consistent quality

Leveraging cutting-edge technology and industry-leading craftsmanship, we ensure your medical device components meet the highest standards of accuracy, reliability, and performance. Partner with us to transform your critical medical projects into manufacturing successes.

How to Implement the QA Measurements in Medical Casting?

In medical die casting, quality is non-negotiable. Every component—whether for surgical tools, implantable devices, or diagnostic equipment—must meet stringent industry standards to ensure patient safety and device reliability. To achieve this, manufacturers must implement rigorous Quality Assurance (QA) measurements throughout the production process.

- Precision Measurement & Inspection Equipment

Medical die casting demands ultra-tight tolerances and flawless surface finishes. To verify part accuracy, manufacturers use:

- CMM (Coordinate Measuring Machines) – For 3D dimensional analysis

- Optical Comparators & Laser Scanners – For high-resolution surface inspection

- X-ray & CT Scanning – To detect internal defects in critical components

- Strict Process Control & Documentation

- Real-Time Process Monitoring – Sensors track pressure, temperature, and cycle times to ensure consistency.

- Statistical Process Control (SPC) – Data-driven adjustments prevent deviations before defects occur.

- Full Traceability – Each batch is logged with material certifications, machine settings, and inspection reports.

- Validation & Compliance Testing

Medical castings must comply with ISO 13485, FDA, and ASTM standards. Key tests include:

- Dimensional & Mechanical Testing (tensile strength, hardness)

- Leak & Pressure Testing (for fluid-handling components)

- Biocompatibility Checks (for implantable parts)

- Skilled QA Personnel & Continuous Improvement

Even with automation, human expertise ensures final validation. QA teams perform:

- First-Article Inspections (FAI) – Before mass production

- Random Sampling & AQL Checks – During production

- Root Cause Analysis (RCA) – For any non-conformities

Why Is Automation Critical for High-Standard Medical Die Casting?

Automation plays a fundamental role in the production of medical die-cast components, including surgical instruments, implantable device parts, and diagnostic equipment gears. Our facility integrates high-precision tooling and a comprehensive range of automated processes, ensuring an optimal balance of:

- Efficiency – Streamlined production cycles for faster turnaround

- Precision – Tight tolerances and repeatable accuracy for critical medical applications

- Consistency – Reliable quality across low- to high-volume production runs

- Cost-Effectiveness – Reduced manufacturing expenses without compromising quality

Our industry-leading capabilities support both low-volume prototyping and large-scale medical die casting, delivering flawless results with minimal defects. While automation drives the majority of the process, skilled human oversight ensures absolute precision at every stage, guaranteeing that each component meets the highest medical standards.

What Are the Top Products of Medical Casting?

Medical casting plays a vital role in producing high-precision components for advanced healthcare equipment. Utilizing rapid prototyping, and die casting technologies, our industry delivers customized, intricate designs with exceptional accuracy and efficiency.

Key products of medical casting include:

Medical monitor support equipment – Durable and ergonomic components for diagnostic devices.

Robotic surgical parts – High-performance parts for precision-driven medical robots.

Dialysis equipment – Reliable and sterilizable components for life-saving machines.

Ophthalmological devices – Intricate, high-tolerance parts for eye care instruments.

Oxygen therapy equipment – Critical components for respiratory and ICU devices.

Insulin & IV pumps – Precision-cast parts ensuring safe drug delivery.

DNA sequencing equipment – Advanced components for genomic research and diagnostics.

With expertise in complex geometries and industry-specific requirements, medical casting enables innovation in modern healthcare technology.

What Die Cast Alloys Are Used for Medical Casting?

In medical casting, selecting the right die-cast alloy is crucial for ensuring precision, durability, and biocompatibility. The most commonly used alloys include aluminum-based materials, particularly aluminum-silicon (Al-Si) and aluminum-silicon-copper (Al-Si-Cu) alloys, due to their excellent casting, mechanical, and thermal properties.

Key Alloys for Medical Casting:

A380

The most widely used die-cast alloy, offering a balanced combination of fluidity, pressure tightness, and resistance to hot cracking.

Its high machinability makes it ideal for medical device components requiring intricate detailing.

ADC12

Known for its superior mechanical properties and dimensional stability, this alloy is preferred for highly complex medical parts.

It provides excellent strength and corrosion resistance, making it suitable for critical healthcare applications.

AlSi12

An aluminum-silicon alloy with outstanding brazing compatibility and flux resistance, often used in medical devices requiring high thermal and mechanical performance.

AlSi9Cu

A high-strength aluminum-silicon-copper alloy used in specialized medical and automation components. Its lightweight yet robust properties make it ideal for surgical instruments and diagnostic equipment.

These alloys ensure precision, reliability, and efficiency in medical casting, meeting the stringent demands of the healthcare industry. Whether for surgical robots, dialysis machines, or implantable devices, these materials provide the necessary durability, corrosion resistance, and biocompatibility for advanced medical applications.

What Does Medical Casting Mean for Medical Equipment and Devices?

In the development of medical equipment, one of the greatest challenges lies in balancing clinical functionality, human factors, environmental adaptability, and—above all—patient safety. As medical device designs grow increasingly complex with advancing technology, manufacturers must prioritize precision, reliability, and efficiency in production.

Key Considerations in Medical Casting for Healthcare Devices:

- Miniaturization & Complexity– Modern medical devices demand smaller, lighter, yet highly intricate components, pushing die casting to deliver high-precision, thin-walled, and structurally sound parts.

- Speed to Market– In a competitive industry, rapid prototyping and efficient die casting processes help manufacturers accelerate production while maintaining strict quality standards.

- Material & Performance Requirements– Medical casting alloys (such as A380, ADC12, AlSi12, and AlSi9Cu3) must meet biocompatibility, corrosion resistance, and mechanical strength criteria for use in surgical tools, implants, diagnostic machines, and wearable devices.

- Patient-Specific Adaptability – Medical equipment must accommodate diverse patient anatomies and clinical environments, requiring customizable, high-tolerance cast components.

Why Choose Die Casting for Medical Devices?

Our industry specializes in high-accuracy die casting, producing sterilizable, durable, and lightweight components for:

-Surgical robots & minimally invasive tools

-Implantable devices & prosthetics

-Diagnostic & monitoring equipment

-Drug delivery systems (insulin pumps, IV components)

By leveraging advanced die casting techniques, we ensure medical devices meet strict regulatory standards (FDA, ISO 13485) while optimizing cost, performance, and production speed. Whether for prototyping or mass production, medical casting remains a cornerstone of innovation in healthcare technology.

What Is the Biocompatibility in Medical Casting of Medical Equipment and Device?

Biocompatibility is a critical factor in medical casting, particularly for devices that interact with human tissues or bodily fluids. While aluminum alloys are commonly used, they are not the only option for manufacturing medical-grade components. The industry has developed specialized casting alloys that meet stringent biocompatibility requirements while maintaining excellent mechanical properties.

Our medical casting solutions utilize a variety of biocompatible alloys, including:

-Aluminum-silicon alloys (AlSi)

-Aluminum-copper alloys (AlCu)

-Custom alloy formulations

These materials undergo rigorous testing and validation processes to ensure they meet:

- ISO 10993 standards for biological evaluation

- FDA requirements for medical devices

- Client-specific validation protocols

The combination of silicon and copper with aluminum creates alloys with enhanced properties:

• Superior corrosion resistance

• Excellent mechanical strength

• Optimal thermal conductivity

• Improved wear resistance

Our casting capabilities allow for precise control over material composition, ensuring each medical component meets exact biocompatibility specifications. We offer comprehensive material selection support, eliminating the need for clients to compromise on performance or regulatory compliance.

For implantable devices or long-term tissue contact applications, we can provide specialized surface treatments to further enhance biocompatibility while maintaining the structural integrity of the cast components. This flexibility in material science and processing makes die casting an ideal manufacturing method for a wide range of medical applications, from surgical instruments to diagnostic equipment.

How Can Surgical Devices Be Specialized through Medical Casting?

Medical casting has revolutionized the production of specialized surgical devices, enabling manufacturers to meet the exacting standards of modern medicine. While aluminum alloys remain a cornerstone for FDA-approved biocompatible devices, today’s medical casting solutions offer far greater material and design flexibility.

Precision Engineering for Surgical Applications:

- Material Versatility – Beyond standard aluminum alloys, we utilize:

-High-performance aluminum-silicon alloys (AlSi)

-Medical-grade magnesium alloys

-Specialized zinc alloys

-Custom alloy formulations for specific applications

- Complex Geometry Capabilities:

-Micro-casting for minimally invasive instruments

-Thin-wall casting for lightweight devices

-Intricate internal channels for fluid management systems

- Regulatory-Compliant Production:

-ISO 13485-certified processes

-Full material traceability

-Biocompatibility testing per ISO 10993 standards

Cost-Effective Specialization Benefits:

- Single-process production reduces assembly requirements

- Near-net-shape casting minimizes post-processing

- High-volume repeatability ensures consistent quality

- Design flexibility allows for rapid device iteration

Our medical casting expertise enables the production of:

• Robotic surgical components

• Electrosurgical instruments

• Orthopedic tools

• Microsurgical devices

• Custom implantable components

By leveraging advanced die casting technologies, we help medical device manufacturers achieve the perfect balance of precision, performance, and cost-efficiency in their surgical equipment. Our capability to produce complex, sterile-compatible components makes medical casting an ideal solution for next-generation surgical devices.

What Role Medical Casting Plays for Therapy and Diagnostic Devices?

Medical casting serves as a critical manufacturing solution for advanced therapy and diagnostic equipment, enabling the production of high-performance components that meet stringent healthcare requirements. Modern medical devices leverage precision casting technology to achieve:

Key Functional Advantages:

- Enhanced Diagnostic Capabilities – Enables production of complex components for:

-Medical imaging systems

-Portable screening devices

-Precision diagnostic tools

- Therapeutic Application Support – Facilitates manufacturing of:

- Drug delivery mechanisms

- Rehabilitation equipment

- Surgical assistance devices

Design and Performance Considerations:

Our die casting solutions address three fundamental medical device requirements:

- Structural Integrity: High-strength alloys ensure device durability in clinical environments

- Ergonomic Optimization: Precision casting enables comfortable, user-friendly designs

- Weight-Function Balance: Lightweight yet robust components for portable applications

Industry-Leading Manufacturing Capabilities:

We provide specialized medical casting services that exceed standard requirements through:

- Advanced Design Flexibility – Complex geometries for customized medical solutions

- Material Expertise – Biocompatible alloys (AlSi, Mg, Zn) for various applications

- Micro-Precision Production – Tight tolerances (±0.05mm) for critical components

- Medical-Grade Surface Finishes – Smooth, sterile-compatible surfaces meeting ISO 13485 standards

Our medical casting technology supports the entire spectrum of healthcare settings – from hospital-grade equipment to home-use diagnostic devices – ensuring reliability, precision, and cost-effectiveness throughout the product life cycle.

What Is the Importance of Medical Casting?

Medical casting stands as a cornerstone of modern healthcare manufacturing, playing a pivotal role in producing precision components for life-saving equipment. As one of the most critical sectors in precision manufacturing, medical casting contributes to approximately 75% of all finished medical device components, representing over one-third of global casting production.

Key Applications in Healthcare:

Our advanced die casting technology enables the production of critical medical components for:

- Diagnostic Equipment

- Portable patient monitors

- Ultrasound imaging systems

- EKG/ECG machines

- Dental X-ray units

- Treatment Devices

- Electronically controlled hospital beds

- Surgical instrument components

- Drug delivery systems

- Portable Medical Solutions

- Hand-held diagnostic tools

- Wearable medical devices

- Home healthcare equipment

Why Medical Casting Matters:

- Precision Engineering: Achieves tight tolerances (±0.05mm) for critical components

- Material Versatility: Utilizes biocompatible alloys (Aluminum, Magnesium, Zinc)

- Cost Efficiency: Enables high-volume production of complex parts

- Regulatory Compliance: Meets strict FDA and ISO 13485 standards

The medical casting industry continues to innovate, developing lighter, stronger, and more complex components that push the boundaries of modern healthcare technology. From emergency room equipment to at-home monitoring devices, die cast medical components ensure reliability, durability, and precision in life-critical applications.

How Is Medical Casting Beneficial in Electronic Medical Devices?

As electronic medical devices evolve with greater sophistication and power demands, precision die casting emerges as the optimal manufacturing solution for their critical components. Our medical casting expertise addresses the unique thermal management challenges of modern healthcare electronics through:

Advanced Thermal Regulation Solutions:

- High-performance die cast heat sinks with optimized thermal conductivity

- Precision-engineered aluminum and magnesium alloy components

- Integrated cooling architectures within device housings

- Custom-designed thermal pathways for targeted heat dissipation

Key Benefits for Medical Electronics:

- Enhanced Device Reliability

- Maintains optimal operating temperatures

- Prevents performance degradation

- Extends equipment lifespan

- Superior Precision Engineering

- ±0.05mm tolerance for sensitive electronic components

- EMI/RFI shielding capabilities

- Vibration-resistant structures

- Design Integration Advantages

- Seamless heat sink incorporation

- Reduced assembly complexity

- Space-saving unified designs

Our Medical Casting Capabilities:

- Proprietary alloys with superior thermal conductivity

- Micro-porosity control for consistent performance

- Medical-grade surface finishes

- Full compliance with ISO 13485 and FDA standards

As the leading provider of die cast components for medical electronics, we enable manufacturers to overcome thermal challenges while meeting stringent healthcare requirements. Our solutions power critical applications including:

• Patient monitoring systems

• Diagnostic imaging equipment

• Portable medical devices

• Surgical robotics

• Wearable health technology

By combining precision die casting with thermal engineering expertise, we deliver components that ensure the reliability, accuracy, and longevity of life-saving medical electronics.

Why Prefer Aluminum in Medical Casting?

Aluminum die casting has become the gold standard for medical device manufacturing, offering unparalleled advantages that meet the stringent demands of the healthcare industry. Here’s why leading medical equipment manufacturers consistently choose aluminum casting solutions:

Superior Material Properties:

- Optimal Strength-to-Weight Ratio: Aluminum alloys provide exceptional durability while remaining lightweight – crucial for portable medical devices and handheld surgical instruments

- Excellent Corrosion Resistance: Naturally forms protective oxide layer, ideal for sterilization processes and bodily fluid exposure

- High Thermal Conductivity: Essential for temperature-sensitive diagnostic equipment and heat-dissipating components

Production Advantages:

- Precision Engineering

- Capable of producing complex, thin-walled geometries with tight tolerances (±0.05mm)

- Maintains dimensional stability for critical medical applications

- Allows integration of multiple features into single cast components

- Cost-Effective Manufacturing

- Faster cycle times compared to other metals

- Reduced secondary machining requirements

- Ideal for medium-to-high volume production runs

- Regulatory Compliance

- Meets FDA and ISO 13485 standards for medical devices

- Biocompatible alloy options available

- Consistent material properties for reliable performance

Medical Applications Benefiting from Aluminum Casting:

• Surgical robotics components

• MRI and CT scanner parts

• Portable diagnostic devices

• Prosthetic and orthopedic equipment

• Drug delivery system components

The combination of aluminum’s material advantages with advanced die casting technology creates the perfect solution for medical manufacturers seeking reliability, precision, and cost-efficiency. As medical devices continue to advance in complexity and functionality, aluminum casting remains the preferred choice for producing high-performance healthcare components that save lives and improve patient outcomes.

What Are the Benefits of Medical Casting?

Medical die casting has become the premier manufacturing

solution for cutting-edge healthcare devices, offering unmatched

advantages for OEMs and medical device engineers. Here are the

key benefits that make it the preferred choice:

Superior Design Capabilities:

- Complex Geometry Realization: Produces intricate net-shape components with internal channels and thin walls (as thin as 0.5mm)

- Precision Engineering: Achieves tight tolerances to ±0.05mm for critical medical applications

- Thermal Management Integration: Enables built-in heat sinks for electronic medical devices

- Minimal Draft Requirements: Allows for near-vertical walls (as low as 0.5° draft angle)

Production Advantages:

- Unmatched Efficiency

- High-volume production capacity (up to 500+ shots/hour)

- Rapid tooling turnaround (2-4 weeks for prototype molds)

- 30-50% faster cycle times compared to alternative processes

- Cost Optimization

- 40-60% lower per-part costs at volume

- Reduced secondary operations (up to 80% machining elimination)

- Material savings through near-net-shape production

- Quality & Compliance

- Consistent part-to-part repeatability (CpK >1.67)

- Meets ISO 13485 and FDA quality standards

- Full material traceability from ingot to finished part

Material & Finish Options:

• Medical-grade aluminum alloys (A380, ADC12)

• Biocompatible magnesium alloys

• Antimicrobial surface treatments

• EMI/RFI shielding coatings

• High-gloss medical finishes

Ideal for Critical Applications:

- Surgical robotics components

- Imaging equipment housings

- Portable diagnostic devices

- Wearable medical technology

- Sterilizable instrument casings

By leveraging medical die casting, manufacturers gain access to a proven process that combines design flexibility with production efficiency – all while meeting the stringent requirements of the healthcare industry. The result? Higher quality devices, faster time-to-market, and significant cost savings throughout the product life cycle.

How to Test the Quality of Medical Casting Products?

Quality assurance in medical die casting requires a rigorous, multi-stage testing protocol to ensure every component meets exacting healthcare standards. Our comprehensive quality control process guarantees the reliability and precision of medical castings through:

Critical Quality Testing Procedures:

- Structural Integrity Verification

- X-ray inspection for internal porosity

- CT scanning for dimensional accuracy

- Pressure testing (up to 500 psi)

- Load-bearing capacity evaluation

- Surface Quality Assessment

- 3D surface profilometry (Ra <0.8μm for implant-grade)

- Microscopic defect detection (50x magnification)

- Coating thickness measurement (±5μm tolerance)

- Material Certification

- Spectrochemical analysis (OES testing)

- Tensile strength testing (UTS >240 MPa)

- Microhardness evaluation (70-90 HB)

- Corrosion resistance validation (ASTM B117)

Advanced Finishing Quality Standards:

- Precision Deburring

- Automated vibratory finishing

- Cryogenic deburring for micro-features

- ECM (Electrochemical Machining) for critical edges

- Surface Enhancement

- Medical-grade shot peening (Almen intensity 0.2-0.4mmA)

- Mirror polishing (Ra 0.05-0.1μm)

- Electropolishing for stainless steel components

- Coating Classification

- Class I (Implant-grade): Anodized, PVD coated

- Class II (Sterilizable): Powder coated, e-coating

- Class III (Structural): Chemical conversion, passivation

- Class IV (Cosmetic): Brushed, bead blasted finishes

Our quality system adheres to:

- ISO 13485:2016 Medical Devices

- FDA 21 CFR Part 820

- EU MDR (Medical Device Regulation)

- ASTM E155 for casting inspection

Each medical casting undergoes 100% dimensional inspection using CMM (Coordinate Measuring Machine) with ±0.01mm accuracy, ensuring perfect compliance with surgical and diagnostic equipment requirements. From prototype to production, we maintain full documentation including:

- Material certificates

- Process validation reports

- First article inspection records

- Lot traceability documentation

This exhaustive quality regimen guarantees that every die cast medical component meets the extreme reliability demands of life-critical healthcare applications.

What Are the Uses of Aluminum in Medical Casting?

Aluminum die casting has revolutionized modern healthcare manufacturing, becoming the material of choice for critical medical equipment across clinical environments. From emergency rooms to surgical suites, aluminum cast components deliver unmatched performance in life-saving applications.

Key Medical Applications of Aluminum Castings:

- Diagnostic Equipment

- MRI and CT scanner components

- Ultrasound transducer housings

- Portable X-ray machine frames

- Patient monitoring system enclosures

- Surgical Solutions

- Robotic surgical arm components

- Minimally invasive instrument bodies

- Electrosurgical device housings

- Operating table mechanisms

- Treatment Devices

- Dialysis machine structural parts

- Infusion pump casings

- Ventilator components

- Physical therapy equipment

Why Aluminum Dominates Medical Casting:

- Material Advantages:

- 60% lighter than steel with comparable strength

- Natural corrosion resistance for sterilization cycles

- Excellent EMI/RFI shielding properties

- Superior thermal conductivity (≈200 W/m·K)

- Manufacturing Benefits:

- Achieves tight tolerances (±0.05mm) for precision instruments

- Enables complex, thin-walled geometries (down to 1mm)

- Cost-effective for medium to high-volume production

- Reduces assembly needs through component integration

- Quality & Compliance:

- Meets ISO 13485 medical device standards

- Complies with FDA 21 CFR requirements

- Biocompatible alloy options available

- Full material traceability from ingot to finished part

Modern healthcare facilities rely on aluminum die cast components for their:

✓ Consistent performance in sterile environments

✓ Durability under frequent disinfection

✓ Lightweight properties for portable devices

✓ Design flexibility for ergonomic solutions

As medical technology advances, aluminum casting continues to enable breakthroughs in diagnostic accuracy, surgical precision, and patient care delivery – making it an indispensable solution for healthcare manufacturers worldwide.

What Are the Medical Technology Requirements for Medical Casting?

Medical die casting must meet exceptionally stringent technological requirements to ensure safety, reliability, and performance in healthcare applications. These components face unique challenges that demand specialized manufacturing solutions:

Critical Technical Requirements:

- Sterilization Compatibility

- Withstands 1000+ autoclave cycles (134°C/273°F)

- Resistant to harsh disinfectants (alcohol, bleach, hydrogen peroxide)

- Maintains structural integrity after repeated sterilization

- Precision Engineering Standards

- Sub-millimeter tolerances (±0.05mm typical)

- Surface finishes down to Ra 0.4μm for implantable devices

- Zero porosity requirements for fluid contact components

- Material Performance Criteria

- Biocompatible alloys (ISO 10993 certified)

- Radiation shielding capabilities (for imaging equipment)

- EMI/RFI protection for electronic components

- Wear resistance for moving parts

Specialized Application Requirements:

- Diagnostic & Surgical Devices:

- Endoscope components requiring:

- Perfect weight balance (typically 200-400g)

- Ergonomic contours for prolonged use

- Seamless surfaces to prevent bacterial adhesion

- Imaging Equipment:

- Lead-free radiation shielding solutions

- Vibration-resistant structures for clear imaging

- Thermal-stable components for sensitive electronics

- Quality Assurance Protocols:

- 100% dimensional inspection via CMM

- Material traceability documentation

- Clean room production for critical components

- Validation testing per FDA 21 CFR Part 820

Our medical casting solutions incorporate:

✓ Antimicrobial surface treatments

✓ Precision-machined mating surfaces

✓ Custom alloy formulations for specific applications

✓ Validated cleaning/sterilization procedures

Meeting these exacting requirements ensures medical cast components perform flawlessly in life-critical applications while complying with global medical device regulations. From surgical robots to portable diagnostics, our die casting technology delivers the precision and reliability modern healthcare demands.