PRECISION ALUMINUM MACHINING SERVICES TAILORED TO YOUR PROJECT NEEDS

Meet your needs for top-quality parts with our end-to-end machining solutions.

Why Choose JUFENG Precision CNC Machining?

JUFENG Precision is your trusted CNC machining partner in China, delivering high-precision aluminum parts with fast turnaround times. Equipped with state-of-the-art CNC centers, we guarantee tight tolerances and superior surface finishes to meet your most demanding project requirements.

Our CNC Machining Services Include:

- Precision CNC Milling

- CNC Turning & Boring

- Drilling & Tapping Operations

With in-house manufacturing capabilities and comprehensive finishing options, we provide cost-effective solutions for both prototyping and production runs. Contact us today for all your precision CNC machining needs!

Complete CNC Machining Solutions

At JUFENG Precision, we provide end-to-end CNC machining services – from precision tooling design to final surface finishing. Our one-stop capability ensures you get finished components without the hassle of multiple suppliers.

Precision Aluminum CNC Machining-Aluminum Alloy

Aluminum alloys are the ideal choices for CNC machining, offering the perfect balance of lightweight properties, excellent machinability, and superior dimensional stability. These characteristics make aluminum perfect for producing high-tolerance, complex components across industries.

Our Premium Aluminum Alloy Selection:

• 5052/5083 (5xxx Series) – Superior corrosion resistance

• 6061/6082 (6xxx Series) – Optimal strength-to-weight ratio

• 7075 (7xxx Series) – Aerospace-grade strength

Engineered for precision, our aluminum machining services deliver components with exceptional surface finishes and tight tolerances – meeting your most demanding specifications.

High Precision Aluminum CNC Machining

We offer comprehensive CNC machining services, utilizing state-of-the-art machining centers that are equipped with all the necessary tools for aluminum part machining. Our advanced equipment and processes enable us to maintain high tolerances and achieve exceptional precision.

Our CNC center features precise CNC lathes machines, 3- 5 axis CNC machines, with precision tolerances up to 0.01mm. This allows us to accommodate a wide range of aluminum machining projects with varying precision requirements.

Our aluminum machining services encompass:

- Aluminum Extrusion

- Aluminum Prototypes

- Machined aluminum die-cast parts

Which offer a full spectrum of capabilities to meet your specific needs.

Aluminum Surface Finishing by JUFENG Precision

JUFENG Precision delivers comprehensive surface finishing solutions for CNC machined aluminum parts, ensuring enhanced durability and aesthetics. Our one-stop services include:

- Anodizing – A durable, corrosion-resistant finish for precision machined components

- Powder Coating & Wet Painting – Protective and decorative coatings for superior wear resistance

- E-Coating – Uniform, high-performance corrosion protection

- Laser Etching & Silk Screening – Permanent marking for branding and part identification

Whether for functional protection or custom aesthetics, our advanced finishing processes meet the highest industry standards. Trust JUFENG Precision for high-quality, precision-engineered aluminum surface treatments.

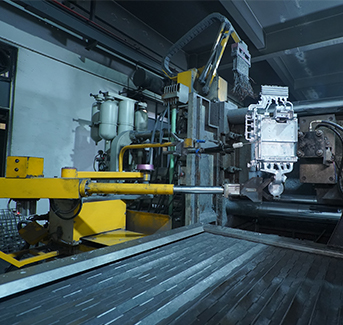

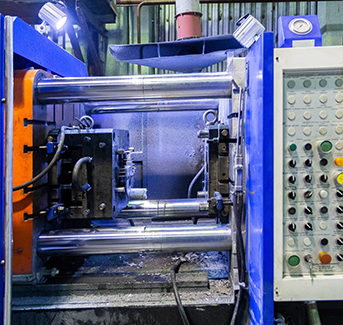

Our Equipment

Comprehensive machines and equipment allow us to provide a customized solution to each customer’s needs. We will continue to invest in superior equipment with technological innovation.

2 sets of 5-axis CNC machines

10 sets of 4-axis CNC machining center

15 sets of 3-axis CNC machining center

12 sets of CNC lathes

CMM

Vision Measurement Systems

3D Scanners

Spectrum Metal Analyzer

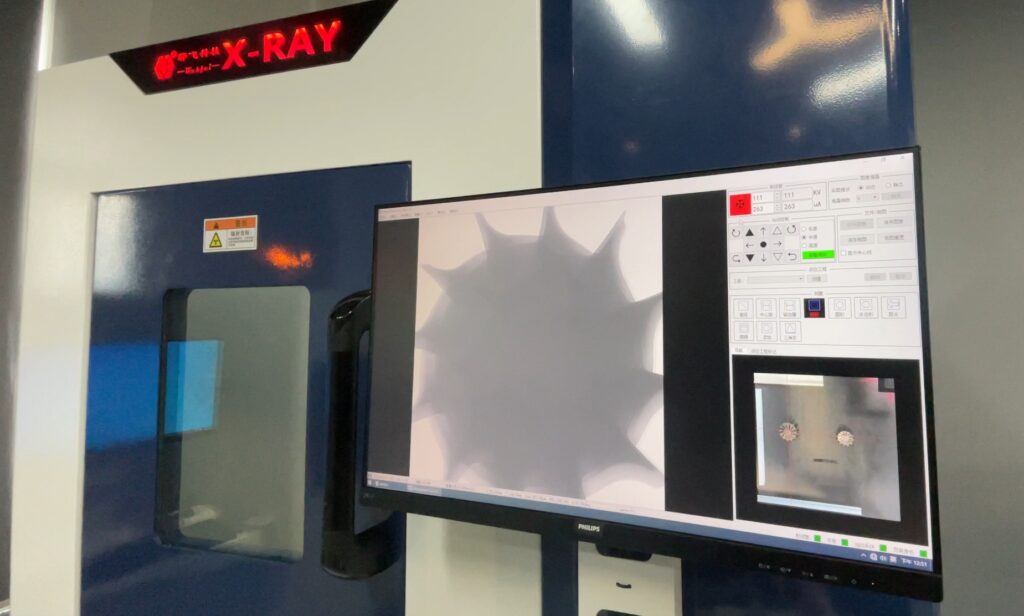

X-Ray detector

Cleanliness Test Equipment

Microscope

Leakage Test Equipment

Salt Spray Testing Equipment

Pneumatic Measuring Instrument

Hardness Testing Machine

Color Meter Machine

Thickness Testing Machine

Engineering Support

Our engineering team partners with you from initial design through production, leveraging advanced CAE tools to optimize rapid prototyping, mold design and final part performance.

Advanced Engineering Capabilities

![]() Design Validation: Pro/Engineer & Pro/Manufacture integration for DFM (Design for Manufacturing)

Design Validation: Pro/Engineer & Pro/Manufacture integration for DFM (Design for Manufacturing)![]() Virtual Simulation: CAD/CAM file optimization in digital environments

Virtual Simulation: CAD/CAM file optimization in digital environments![]() Process Simulation: Mold flow, solidification, and cooling analysis to prevent defects

Process Simulation: Mold flow, solidification, and cooling analysis to prevent defects![]() Value Engineering: Cost-reduction strategies without compromising quality

Value Engineering: Cost-reduction strategies without compromising quality

Die Casting Quality Assurance

The top priority of JFUFNEG Precision is to meet our customer’s expectations in quality, delivery and services. The following certified quality system, allows us to serve automotive, medical, telecom, robotics, lighting and other critical industry applications.

IATF 16949

ISO 13485

ISO 9001

ROHS & REACH

Our Laboratory

Conscientious employees put an extraordinary amount of care into every process with the help of professional and sophisticated instruments to ensure that our customers’ products meet their expectations.

CMM Equipment

Full dimensions measuring for die casting parts

Strict IPQC

Perform inspections during process quality control

X-ray Inspection

Detect the porosity condition of die casting parts

Die Casting Products Gallery

We specialize in manufacturing both small, intricate die castings and large, complex components—ensuring consistent quality across all volumes—serving automotive, medical, robotics, telecom, lighting, and consumer electronics applications.

The Voices from Our Clients

We always listen to our customers’ opinions, value their feedback to continuously optimize our processes and improve our products and services.

Michael

기술 바이어(미국)

주펑정밀과의 파트너십에 진심으로 감사드립니다. 귀사 제품의 품질과 성능이 눈에 띄게 향상되었으며, 내년은 양사 모두에게 성공적인 한 해가 될 것이라고 확신합니다. 비용 절감을 주도하고 정시 납품을 보장해 주신 귀사의 팀에 특별히 감사드리며, 귀사의 지원이 큰 힘이 되었습니다.

David

프로젝트 엔지니어(영국)

JUFENG Precision은 새로운 프로젝트든 진행 중인 생산 부품이든 지속적으로 우수성을 제공합니다. 그들의 광범위한 전문 지식과 강력한 지원은 매우 유익합니다. 특히 뛰어난 DFM 역량, 신속한 대응, 안정적인 정시 납품에 감사하고 있습니다.

Marco

Mechanical Engineer & Technical Buyer (EU)

JUFENG Precision provides high-quality components that meet our specifications. We anticipate further strengthening our partnership in the coming year through expanded cooperation.

Who We Work With

We are looking forward to working with you and be your trustworthy & reliable partner in any die castings or CNC machining parts demands.

CNC Machining Service FAQ

Nowadays, aluminum processing services are becoming more and more popular. Due to the high machinability of aluminum and the low-cost process, you can now get the best quality machined products at a lower price!

However, finding the right manufacturer, communicating with them effectively, and finally placing an order with the product you want is not a simple task.

Many small variables can have a huge impact on the design and quality of your product. Before placing an order, you need to understand all the details of it.

This article aims to let you understand the most important things that you need to know and consider before ordering aluminum processing services in China.

최신 글

What is CNC Machining Service?

CNC machining is an advanced manufacturing process that uses computer-controlled machines to precisely shape materials by removing excess stock. Operating across multiple axes (typically 3-5), our CNC systems transform digital CAD/CAM designs into high-accuracy components for both prototyping and production applications.

Key Advantages of Our CNC Machining Services:

- Exceptional Precision: Achieve tolerances within ±0.01mm

- Rapid Production: Faster than traditional machining methods

- Material Versatility: Capable of machining various metals, plastics, and composites

- Repeatable Accuracy: Perfect for both one-off prototypes and mass production

Our CNC Capabilities Include:

✓ Multi-axis Milling

✓ Precision Turning

✓ Drilling & Tapping

✓ Surface Grinding

At JUFENG Precision, we combine state-of-the-art CNC technology with engineering expertise to deliver optimal machining solutions tailored to your specific project requirements. From design optimization to final production, we ensure every component meets your exact specifications.

Why Choose Our CNC Services?

• Advanced 3-5-axis machining centers

• ISO-certified quality control

• DFM (Design for Manufacturing) support

• Competitive lead times

Let our CNC machining experts help bring your designs to life with unmatched precision and efficiency. Contact us today to discuss your project requirements.

Why Choose Aluminum CNC Machining Services?

Aluminum CNC machining delivers the ideal combination of precision, performance and cost-efficiency for custom manufactured components. Here’s why industry leaders prefer aluminum:

Key Advantages:

✓ Superior Machinability – Faster processing speeds reduce production costs

✓ Optimal Strength-to-Weight Ratio – 60% lighter than steel with comparable durability

✓ Natural Corrosion Resistance – Ideal for demanding environments

✓ Excellent Thermal Conductivity – Perfect for heat-sensitive applications

Industry Applications:

• Transportation – Reduces vehicle weight by 20-30%, improving fuel efficiency and safety (energy absorption)

• Aerospace – Accounts for 75-80% of modern aircraft structures

• Industrial Equipment – Combines lightweight properties with vibration damping

• Consumer Products – Enables sleek, durable designs

Technical Benefits:

- Achieves surface finishes without secondary processing

- Maintains dimensional stability across temperature variations

- Compatible with all standard CNC processes (milling, turning, drilling)

- Recyclable material supports sustainable manufacturing

At JUFENG Precision, our aluminum machining expertise helps OEMs across industries optimize part performance while reducing production costs. Request a quote for your next project today.

How to Select a Trusted Aluminum CNC Machining Partner in China

Choosing the right aluminum machining supplier in China requires careful evaluation of both technical capabilities and operational reliability. Here are key factors to consider:

- Verify Manufacturer Credentials

- Check business licenses and industry certifications (ISO, IATF, etc.)

- Review their portfolio of completed projects and client references

- Assess Production Capabilities

- Factory Inspection (On-site or virtual): Confirm their CNC equipment (e.g., 5-axis mills, Swiss-type lathes), quality control processes, and workforce expertise

- Machine Quality Matters: Ensure they use high-precision CNC machines (e.g., DMG ) for consistent results

- Evaluate Communication & Transparency

- Prefer suppliers with fluent English-speaking project managers to avoid misunderstandings

- Regular updates on order status and proactive issue resolution

- Technical Expertise

- Skilled engineers for Design for Manufacturing (DFM) feedback

- Material traceability and testing reports (e.g., alloy composition, hardness)

- Logistics & Support

- Clear contracts covering IP protection, lead times, and after-sales service

- Experience in shipping to your region (INCOTERMS understanding)

Pro Tip: If an on-site visit isn’t feasible, request a live video tour or third-party inspection reports.

Why This Matters:

A qualified supplier ensures precision-machined aluminum parts that meet your specs, on time and within budget.

Our Commitment to Precision Aluminum Machining Quality

At JUFENG Precision, quality isn’t just a process – it’s our foundation. Here’s how we guarantee exceptional standards in every aluminum component we produce:

- Material Excellence

- Strict aerospace-grade aluminum alloy selection (6061-T6, 7075, etc.)

- Certified material traceability with mill test reports

- No material substitutions

- Advanced Manufacturing Capabilities

- State-of-the-art 5-axis CNC machining centers

- Tight tolerance control (±0.05 standard, ±0.01 achievable)

- In-process monitoring with automated measurement systems

- Skilled Technical Team

- ASME-certified machinists with 10+ years average experience

- Dedicated engineering support for DFM optimization

- Continuous staff training on latest machining techniques

- Comprehensive Quality Assurance

- Multi-stage inspection protocol:

-Incoming material verification

-First-article inspection (FAI)

-In-process dimensional checks

-Final comprehensive quality audit - Equipped with CMM, optical scanners, and surface roughness testers

- ISO 9001 certified quality management system

- Traceability & Documentation

- Full dimensional inspection reports with each shipment

- Material certifications available upon request

- Complete production history maintained for 10+ years

We don’t just meet standards – we redefine them. Every machined component undergoes our rigorous quality checklist before shipment.

Why It Matters:

- 99.8% on-time delivery rate

- <0.2% defect rate industry-wide

- 40% repeat business from Fortune 500 clients

Contact our quality team to discuss your project requirements and receive our full quality assurance protocol.

Understanding Custom CNC Aluminum Machining Costs

At JUFENG Precision, we believe in transparent pricing for CNC machining services. Here are the key factors that determine your project’s cost:

- Design Complexity

Simple designs: Lower programming and machining costs

Complex geometries: Require more:

• Engineering time (+15-30%)

• Machine time (+20-50%)

• Material waste (+10-25%)

- Equipment & Machining

Machine type:

• 3-axis: 35−35−75/hour

• 5-axis: 75−75−120/hour

Tolerance requirements:

• Standard (±0.05): Base cost

• Tight (±0.01): +25-40%

- Material Selection

- 6061 Aluminum: 3.50−3.50−5.00/lb (general purpose)

- 7075 Aluminum: 9.00−9.00−12.00/lb (aerospace grade)

- Material yield impacts cost (complex parts waste more)

- Secondary Operations

Surface finishes:

• Basic deburring: Included

• Anodizing: +0.50−0.50−2.00/part

• Powder coating: +1.50−1.50−3.50/part

Additional processes (heat treating, etc.)

- Order Volume

- Prototype (1-10 pieces): Higher unit cost

- Production (500+ pieces): 30-60% cost reduction

- MOQ discounts available

- Logistics

- Shipping costs typically 3-8% of order value

- Expedited shipping: +25-100%

Cost-Saving Tips:

✓ Simplify designs where possible

✓ Choose 6061 over 7075 for non-critical applications

✓ Plan for standard tolerances

✓ Consolidate orders for volume discounts

Get an Accurate Quote:

Submit Your CAD Files for a detailed, no-obligation cost analysis within 24 hours.

Why Our Clients Choose Us:

• 15+ years aluminum machining experience

• DFM recommendations to optimize costs

• Competitive pricing with no hidden fees

• Transparent breakdown of all cost factors

Aluminum CNC Machining Processes Explained

At JUFENG Precision, we utilize advanced CNC technologies to deliver precision aluminum components. Here are the core machining processes we employ:

- CNC Milling (Most Versatile)

- 3-5 axis milling centers

- Ideal for complex geometries and tight tolerances (±0.05 standard)

- Capable of producing pockets, slots, and intricate contour

- CNC Turning (For Rotational Symmetry)

- Swiss-type and conventional lathes

- Best for cylindrical parts and high-volume production

- Typical tolerance range: ±0.01-±0.05

- Combined milling/turning available for complex parts

- Precision Drilling

- High-speed drilling up to 15,000 RPM

- Capable of micro-drilling (down to 0.3mm diameter)

- Includes tapping and thread milling capabilities

- Surface Grinding

- Achieves surface finishes to 16Ra

- Super flatness tolerance

- Essential for mating surfaces and precision assemblies

Advanced Capabilities:

• High-Speed Machining (HSM) for aluminum

• Multi-axis simultaneous machining

• In-process measurement and compensation

Why Aluminum Machines So Well:

✓ Excellent chip formation

✓ Low tool wear rates

✓ High thermal conductivity

✓ Suitable for all CNC processes

Contact our engineers to determine the optimal machining process for your aluminum components.

Optimizing Wall Thickness for Aluminum CNC Machined Parts

At JUFENG Precision, we engineer aluminum components to achieve the perfect balance between lightweight design and structural integrity. Here are the key considerations for minimum wall thickness:

Recommended Guidelines:

- Standard Minimum Thickness: 0.5mm (0.020″) for most applications

- High-Precision Capability: Down to 0.3mm (0.012″) with our 5-axis CNC systems

- Critical Factors Affecting Minimum Thickness:

-Alloy selection (6061 vs 7075)

-Part geometry complexity

-Required surface finish

-Post-machining treatments

Why It Matters:

✔ Maintains dimensional stability during machining

✔ Prevents tool deflection and vibration

✔ Ensures proper heat dissipation

✔ Guarantees structural reliability

Our Advanced Solutions:

- High-speed machining (HSM) for thin-wall applications

- In-process monitoring to prevent distortion

- DFM analysis to optimize your designs

For specialized thin-wall machining projects, contact our engineering team for a free design evaluation. We’ll help you push the limits while maintaining part quality.

Steel vs. Aluminum Machining: Key Technical Differences

At JUFENG Precision, we machine both materials daily. Here’s our professional comparison:

- Machinability

Aluminum:

✓ 3-4x faster machining speeds

✓ Lower cutting forces (30-50% less than steel)

✓ Superior chip formation

Steel:

✓ Requires slower RPM and feed rates

✓ Higher tool wear (3-5x more frequent bit changes)

✓ Often needs coolant for thermal management

- Material Properties

Aluminum Steel

|———————————— | —————————- | ————–

Thermal Conductivity | 120-180 W/mK | 15-50 W/mK

Density | 2.7 g/cm³ | 7.8 g/cm³

Melting Point | 660°C | 1370-1530°C

EDM Speed | 2-3x faster | Standard - Production Considerations

Aluminum Advantages:

• 40-60% shorter lead times

• Lower energy consumption

• Reduced tooling costs

• Better for complex geometries

Steel Advantages:

• Higher strength requirements

• Extreme temperature applications

• Superior wear resistance

- Cost Factors

Aluminum machining typically costs 25-40% less

Steel requires more:

• Machine time

• Tool replacements

• Energy consumption

Expert Recommendation:

For most applications (80%+), aluminum provides the optimal balance of performance and cost-efficiency. However, our engineers can help you select the right material based on your specific:

✓ Load requirements

✓ Environmental factors

✓ Budget constraints

✓ Timeline needs

Contact our material specialists for a free project evaluation and material selection advice.

Flexible Order Quantities for Aluminum CNC Machining

At JUFENG Precision, we break the mold of traditional manufacturing constraints with our adaptable order policy:

Our MOQ Advantage:

✓ Prototype-Friendly: Accept orders from 1 piece

✓ Small-Batch Specialists: Ideal for 10-500 piece runs

✓ Volume Production: Capable of 10,000+ unit orders

✓ High-Mix Expertise: Perfect for complex product portfolios

Why Customers Choose Our Flexible Approach:

• No Compromise Quality – Same precision standards regardless of order size

• Advanced Capabilities – 5-axis CNC machines handling complex geometries

• Streamlined Communication – Dedicated project managers for every order

• Scalable Solutions – Seamless transition from prototyping to full production

Your vision matters – whether it’s one perfect prototype or ten thousand production parts. Our engineering team delivers equal attention to detail at every quantity.

Get an Instant Quote – No order too small, no design too complex.

Key Differentiators:

→ 72-hour turnaround for prototype orders

→ Volume pricing breaks at 100/500/1000 units

→ DFM feedback included with every quote

→ Full documentation package with all shipments

Key Advantages of Aluminum CNC Machining Services

Aluminum stands as the premier choice for precision machining across industries. Here’s why leading manufacturers prefer aluminum components:

- Superior Machinability

- 3-4x faster machining speeds vs. steel

- Lower cutting forces reduce tool wear by 40-60%

- Excellent chip formation enables complex geometries

- Achieves surface finishes to 32Ra without polishing

- Cost Efficiency

- 30-50% lower machining costs than steel

- Reduced energy consumption (15-20% less power)

- Faster production cycles increase output

- Minimal tool replacement requirements

- Material Performance

- Strength-to-Weight: Comparable to steel at 1/3 the weight

- Corrosion Resistance: Natural oxide layer protects against rust

- Thermal Conductivity: 5x better than steel (120-180 W/mK)

- Electrical Conductivity: 60% of copper at 30% the weight

- Industry-Specific Benefits

- Aerospace: 80% of aircraft structural components

- Automotive: 20-30% vehicle weight reduction

- Electronics: Optimal heat dissipation

- Medical: Biocompatible and sterilizable

- Sustainable Manufacturing

- 100% recyclable without quality loss

- Lower carbon footprint in production

- Meets global environmental standards

Technical Specifications:

• Tolerance range: ±0.05 (standard), ±0.01 (precision)

• Alloy options: 6061, 7075, 2024, 5052

• Surface treatments: Anodizing, powder coating, chem film

Aluminum CNC Machining Lead Times: What to Expect

At JUFENG Precision, we optimize production to deliver high-quality aluminum parts efficiently. Here’s our standard lead time breakdown:

Typical Lead Times

- Prototypes (1–10 pcs): 5–7 business days

- Small Batch (10–100 pcs): 7–10 business days

- Medium-Large Orders (100+ pcs): 10–15+ business days (varies by volume)

Factors Affecting Lead Time

✔ Design Complexity – Intricate geometries (+2–5 days)

✔ Material Availability – Standard alloys (6061, 7075) ship fastest

✔ Tolerances – Tight tolerances (±0.01) may require additional machining time

✔ Surface Finishing – Anodizing, plating, etc. (+1–3 days)

✔ Order Volume – Higher quantities scale with optimized production scheduling

How We Ensure Fast Turnaround

- In-house machining & finishing – No outsourcing delays

- Advanced CNC capacity – 50+ machines running 24/7

- Dedicated QC team – Real-time inspection minimizes rework

- Expedited options – Rush services available (inquire for details)

Need parts faster? Contact us for priority scheduling and real-time lead time estimates based on your project specs.

The Advantages of High-Speed Machining (HSM) for Aluminum

At JUFENG Precision, we employ high-speed machining to deliver superior aluminum components with unmatched efficiency. Here’s why HSM is our preferred method:

Key Benefits of HSM:

✓ 60-70% Faster Cycle Times vs conventional machining

✓ Improved Surface Finish (Achieving 16-32Ra consistently)

✓ Extended Tool Life (40-60% longer than standard machining)

✓ Tighter Tolerances (±0.01 achievable)

✓ Reduced Heat Buildup (Eliminating thermal distortion)

Technical Superiority:

• Spindle Speeds: 15,000-30,000 RPM capabilities

• Chip Load Optimization: Maximizing material removal rates

• Adaptive Toolpaths: Intelligent software for optimal cutting

• Dry Machining Possible: Eliminating coolant costs

Production Advantages:

- 30-50% lower per-part costs

- Faster time-to-market for prototypes

- Increased machine utilization

- Energy-efficient operations

Quality Outcomes:

→ Superior dimensional accuracy

→ Exceptional surface integrity

→ Minimal residual stresses

→ Consistent repeatability

Optimizing Efficiency in Aluminum CNC Machining

At JUFENG Precision, we’ve developed a comprehensive approach to maximize machining efficiency without compromising quality. Here’s our proven methodology:

- Advanced Machining Technology

- High-Speed Machining (HSM) systems operating at 20,000+ RPM

- 5-axis simultaneous machining reduces setups by 60%

- Adaptive toolpaths that optimize material removal rates

- Design for Manufacturing (DFM)

- Early engineering collaboration to simplify complex geometries

- Standardized design features that reduce machining time

- Tolerance optimization to minimize secondary operations

- Smart Production Planning

- Nesting software that maximizes material utilization

- Automated tool changers reducing idle time

- Predictive maintenance for 98% machine uptime

- Process Innovations

- High-efficiency cutting tools (HEM) for aluminum

- Minimum quantity lubrication (MQL) systems

- In-process quality verification

Key Results:

→ 50-70% faster than conventional machining

→ 30% reduction in production costs

→ 45% improvement in material yield

→ 99% on-time delivery rate

Efficiency-Boosting Services:

✓ Free DFM analysis with every quote

✓ Rapid prototyping in as little as 72 hours

✓ Volume production scaling options

✓ Just-in-time inventory management

Request a Productivity Assessment – Our engineers will analyze your parts and recommend specific efficiency improvements.