JUFENG Precision Quality System

At JUFENG Precision, we have implemented a rigorous Quality Management System that forms the foundation of our die casting operations. Our system integrates all aspects of production – from process engineering and material selection to technological implementation and methodology – ensuring strict compliance with both customer specifications and international quality standards.

ISO 9001

Specifies requirements for a quality management system for an organization in the following ways:

- Strengthen the ability to deliver high-quality products.

- Meet all relevant regulatory and statutory requirements.

- Achieve high levels of customer satisfaction and develop relationships.

- Strengthen quality management systems and promote corporate efficiency.

- Enhance quality awareness of all employees and improve corporate culture.

IATF 16949

The International Standard, combined with applicable customer-specific requirements, defines the fundamental quality management system requirements for automotive production,service and/or accessory parts organizations.

Companies must strive to achieve:

- Continuous improvement in processes and quality standards.

- Regular efforts to achieve customer satisfaction with products and services.

- Prevent product defects and reduce non-conforming products.

- Promote procedures to reduce change and waste.

- Improve production efficiency and train all staff accordingly.

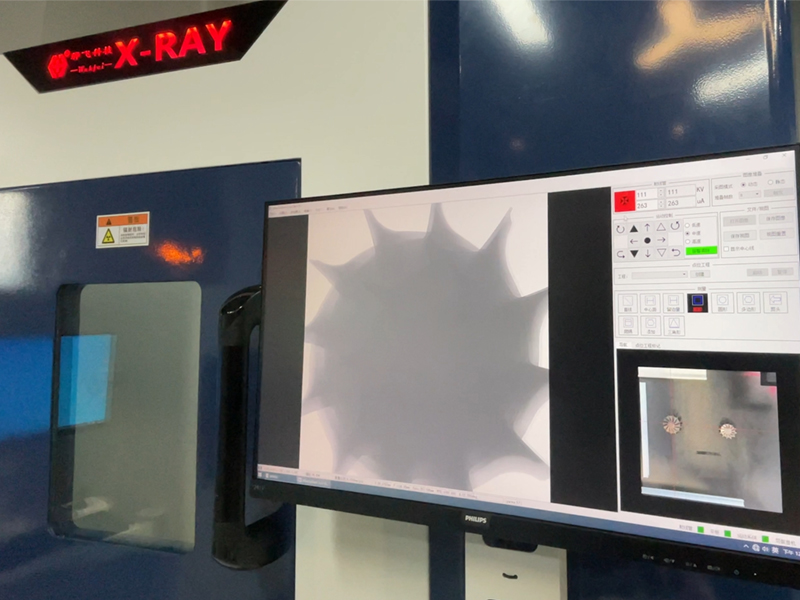

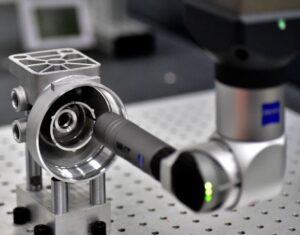

Advanced Laboratory Facility

JUFENG Precision is equipped with advanced QA test facilities to ensure dimensional accuracy. Equipment includes CMM machine, X-ray detection machine and other supportive tools.

Calliper check

CMM machine

X-ray detection

JUFENG Precision Quality System Capabilities

With over a decade of precision die casting expertise, JUFENG has established itself as a premier manufacturer serving global clients with exceptional quality and service. Our ISO 9001:2015 and IATF 16949:2016 certifications demonstrate our unwavering commitment to automotive-grade quality standards, making us the trusted partner of choice worldwide.

Commitment to Precision Die Casting Excellence

At JUFENG, we manufacture premium die cast components that set industry benchmarks for precision and quality. Our production philosophy integrates advanced technology with rigorous quality protocols to deliver defect-free components for demanding applications across global markets.

Uncompromising Quality Assurance

Our manufacturing excellence is built on three foundational pillars:

- Material Integrity

- Premium-grade aluminum alloys with certified composition

- Incoming material spectroscopy verification

- Controlled melting and degassing processes

- Precision Engineering

- ±0.05mm dimensional accuracy standards

- Automated process monitoring systems

- Comprehensive first-article inspection protocols

- Surface Perfection

- Ra 1.6μm standard surface finish

- Custom texture simulation capabilities

- Multiple finishing options (anodizing, powder coating, plating)

Technical Superiority in Every Component

JUFENG die cast products deliver exceptional performance through:

✔ Thermal Stability – Withstand operating temperatures up to 300°C

✔ Structural Integrity – Consistent wall thicknesses from 0.8mm to 12mm

✔ Design Flexibility – Complex geometries with tight tolerances

✔ Material Purity – Controlled porosity below 0.1%

✔ Production Efficiency – High-pressure die casting cycles under 60 seconds

Value-Added Manufacturing Solutions

Our precision die casting capabilities provide significant advantages to partner industries:

- Cost Optimization: Reduced secondary machining requirements

- Weight Reduction: Lightweight aluminum solutions without strength compromise

- Supply Chain Efficiency: Just-in-time delivery with complete traceability

- Sustainability: Closed-loop recycling of production materials

Every JUFENG component embodies our commitment to delivering superior quality, performance, and value – from prototype to full-scale production.

Building Lasting Partnerships Through Value Creation

At JUFENG, our customer-oriented philosophy drives us to deliver more than just precision die cast components – we create meaningful partnerships that foster mutual growth. Our commitment to excellence extends beyond manufacturing to encompass every aspect of client engagement.

Tailored Solutions for Diverse Needs

We differentiate ourselves through:

Flexible Partnership Models

- Accommodating orders from prototype (1-100 pieces) to full production runs

- Customized payment and delivery terms

- Dedicated project management for startups and SMEs

Inclusive Business Approach

- No minimum order quantity restrictions

- Shared cost-reduction initiatives

- Technical support regardless of order size

Quality That Builds Trust

Our customer satisfaction framework includes:

✓ Standardized Excellence

- Consistent adherence to ISO 9001 and IATF 16949 standards

- Transparent quality reporting

- Regular customer quality audits

✓ Continuous Improvement

- Quarterly customer satisfaction surveys

- Dedicated account improvement teams

- Annual customer appreciation workshops

✓ Knowledge Sharing

- Free DFM (Design for Manufacturing) consultations

- Regular technology update seminars

- On-demand process optimization advice

We measure our success by our clients’ achievements. Whether you’re a startup innovator or an established OEM, JUFENG provides the perfect balance of quality, flexibility and cost-efficiency to help your business thrive in competitive markets.

JUFENG Quality System: ISO 9001 & IATF 16949 Certification Excellence

As a leading aluminum die casting manufacturer, JUFENG proudly maintains both ISO 9001:2015 and IATF 16949:2016 certifications – the gold standards in quality management for manufacturing industries. These certifications validate our commitment to operational excellence and customer satisfaction in every component we produce.

Our Certified Quality Management Systems

ISO 9001:2015 Quality Standard

The internationally recognized framework that governs our quality operations:

Key Implementation Features:

- Regulatory Compliance: Strict adherence to all applicable industry standards and customer specifications

- Process Optimization: Continuous improvement of manufacturing workflows and quality control measures

- Workforce Development: Comprehensive training programs to maintain quality awareness across all levels

- Documented Excellence: Meticulous record-keeping of all quality-related processes and improvements

- Resource Management: Strategic allocation of human and technical resources for maximum efficiency

- End-to-End Quality: Rigorous controls from design phase through final delivery

- Preventive Action: Regular internal audits and corrective measures to maintain system integrity

IATF 16949:2016 Automotive Standard

The technical specification that elevates our automotive die casting capabilities:

Advanced Quality Protocols:

- Variation Reduction: Statistical process control for consistent output

- Defect Prevention: Advanced failure mode and effects analysis (FMEA)

- Customer-Centric Approach: Special requirements management for automotive clients

- Supply Chain Excellence: Certified supplier quality management system

The JUFENG Quality Advantage

Our dual certification status translates into tangible benefits for our partners:

- Technical Leadership

- 15+ years of certified die casting expertise

- Automotive-grade quality for all industries

- Advanced process capability studies (CpK > 1.67)

- Customer Assurance

- 98.7% on-time delivery performance

- PPAP documentation for all production parts

- Full material traceability systems

- Continuous Innovation

- Annual R&D investment exceeding 5% of revenue

- Quarterly process improvement initiatives

- Real-time production monitoring systems

- Workforce Excellence

ASQ-certified quality engineers

- Cross-functional quality circles

- 40+ hours annual training per employee

- Sustainable Quality

- Closed-loop corrective action system

- Lean manufacturing principles

- Waste reduction programs

At JUFENG, our certified quality systems aren’t just credentials – they represent our fundamental approach to manufacturing excellence. By integrating these rigorous standards into every aspect of our operations, we deliver die cast components that consistently meet the most demanding specifications while driving continuous improvement throughout our organization.

Precision Quality Assurance in Die Casting Manufacturing

At JUFENG, we’ve built our reputation on a foundation of rigorous quality control systems that deliver exceptional die cast components while accelerating time-to-market for our clients. Our integrated quality management approach combines certified processes with cutting-edge inspection technology to ensure every part meets exacting standards.

Certified Quality Management Framework

Our quality systems are designed to exceed expectations at every production stage:

ISO 9001 & IATF 16949 Compliance

- Comprehensive process documentation and control plans

- Advanced Product Quality Planning (APQP) implementation

- Statistical Process Control (SPC) monitoring

- Production Part Approval Process (PPAP) certification

Efficiency-Driven Production Protocols

- Rapid prototyping with 72-hour typical turnaround

- High-speed tooling development

- Streamlined production workflows

- Just-in-time delivery systems

Advanced Quality Verification Systems

JUFENG employs state-of-the-art inspection technology:

Defect Detection

- X-ray inspection for internal porosity analysis

- Cleanliness testing for particulate contamination

Dimensional Verification

- Zeiss Coordinate Measuring Machines (CMM)

- High-precision digital calipers

- Automated optical measurement systems

Material Performance Testing

- Salt spray chambers for corrosion resistance

- Coating thickness gauges

- Colorimetric analysis for surface treatments

Continuous Quality Improvement

Our dynamic quality approach includes:

- Real-time production monitoring with IoT sensors

- Monthly quality KPI reviews

- Cross-functional quality improvement teams

- Customer feedback integration loops

- Annual quality technology upgrades

The JUFENG Quality Promise

When you partner with us, you benefit from:

✔ Automotive-grade quality standards

✔ 98.7% on-time delivery record

✔ Full material traceability

✔ Comprehensive quality documentation

✔ Dedicated quality engineering support

Our commitment to quality excellence has made us the preferred die casting partner for global OEMs across industries. From prototype to production, JUFENG delivers precision components that meet your most demanding specifications while maintaining competitive lead times and cost efficiency.

Technical Excellence Through Specialized Engineering Teams

At JUFENG, our engineering and quality control departments form the backbone of our precision die casting operations. Comprised of industry veterans and technical specialists, this cross-functional team delivers innovative solutions while maintaining uncompromising quality standards.

Advanced Technical Capabilities

Our engineering teams bring cutting-edge expertise to every project:

Continuous Professional Development

- Quarterly technical training programs

- Certification in latest simulation software (MAGMA, AnyCasting)

- Regular industry conference participation

- Cross-training across multiple manufacturing disciplines

Customer-Oriented Engineering Support

- DFM (Design for Manufacturing) analysis

- Mold flow simulation services

- Tolerance stack-up analysis

- Material selection consulting

- Rapid prototyping guidance

Quality Control Excellence

JUFENG’s quality assurance team implements rigorous controls:

Multilevel Inspection Protocols

- In-process dimensional verification

- First-article comprehensive inspection

- Final audit inspection

- Batch sampling testing

Specialized Quality Roles

- ASQ-certified quality engineers

- Metrology specialists

- Materials testing technicians

- Process validation experts

Why Partner with JUFENG’s Technical Team?

Industry-Leading Expertise

- 15+ years average team experience

- 50+ engineering professionals

- 20+ quality control specialists

- 10+ metallurgists and materials scientists

Proven Technical Advantages

- 98.5% first-pass yield rate

- ±0.05mm dimensional accuracy

- 72-hour typical prototype turnaround

- Full PPAP documentation capability

Comprehensive Service Offering

- Complete die casting solutions from design to delivery

- Secondary operations including CNC machining

- Surface treatment finishing options

- Full assembly and testing services

Our technical teams work collaboratively to:

✓ Optimize designs for manufacturability

✓ Reduce total production costs

✓ Accelerate product development cycles

✓ Ensure consistent quality output

✓ Solve complex engineering challenges

Whether you require high-volume production or specialized low-volume components, JUFENG’s engineering and quality control teams have the expertise to deliver precision die cast solutions that meet your most demanding requirements. Contact us today to discuss how our technical capabilities can benefit your next project.