HIGH PRECISION ALUMINIUM DIE CASTING MANUFACTURER IN ASIA

Meet your needs for top-quality parts with our end-to-end die casting solutions.

Why Choose JUFENG Precision for Your Aluminum Die Casting Needs?

JUFENG Precision is a leading aluminum die casting manufacturer based in China, specializing in high-quality, high-precision die-cast components. We provide end-to-end solutions—from mold design to casting, machining, surface finishing, and logistics—ensuring superior quality and cost efficiency for your projects.

- One-Stop Precision Die Casting Supplier – Full-service support from mold to mass production.

- 15+ Years of Industry Expertise – Reliable solutions backed by extensive experience.

- IATF 16949 & ISO9001 Certified – Compliant with international quality standards.

Your Trusted Die Casting Partner

With cost-effective manufacturing, a skilled engineering team, and flexible production capabilities, we empower your success in industries such as automotive, medical, robotics, telecommunication, and lighting, etc.

Choose JUFENG Precision for high-mix, low-to-medium volume production with consistent quality and on-time delivery. Let’s bring your designs to life with precision and efficiency!

Comprehensive Die Casting Solutions – End-to-End Precision

At JUFENG Precision, we deliver full-service die casting solutions, from rapid prototyping and custom mold design & manufacturing to high-quality die casting, precision CNC machining, and premium surface finishing.

Our global expertise ensures high-performance, cost-effective die-cast components tailored to your exact specifications—wherever your operations are located.

Your trusted partner for precision die casting – from concept to final product.

Precision Mold Manufacturing – Engineered for Performance & Efficiency

Expert Mold Design & Development

Backed by 15+ years of specialized experience, our engineering team delivers high-precision mold design, fabrication, and maintenance—optimized for fast turnaround and long-term reliability.

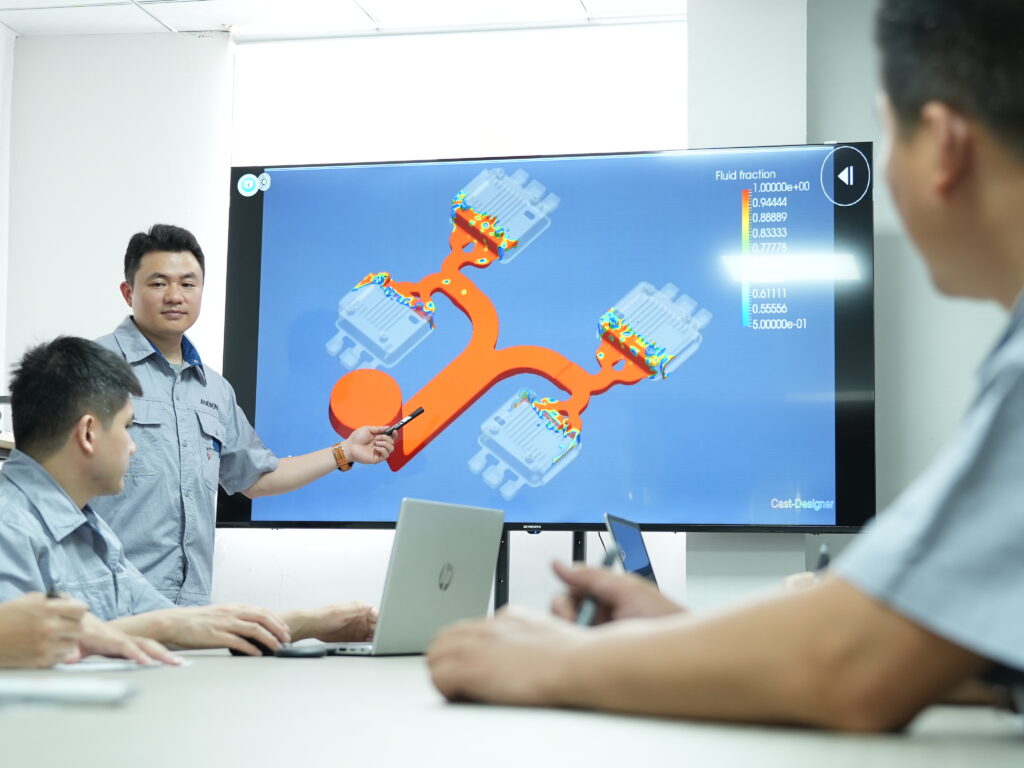

Smart Manufacturing Solutions

Our advanced mold flow simulation proactively eliminates defects, reducing production downtime and costs. Combined with deep process expertise, we ensure your projects run smoothly from first shot to full-scale production.

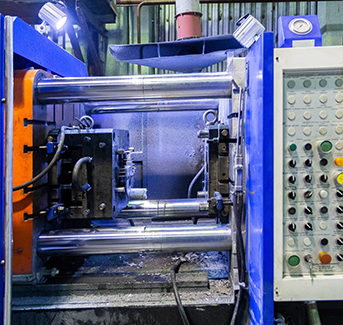

Aluminum Die Casting Solutions - Precision Engineered for Excellence

Uncompromising Quality & Consistency

We specialize in high-tolerance aluminum die casting with superior surface finishes, ensuring your dimensional accuracy and aesthetic requirements are consistently met – and exceeded.

Your Collaborative Manufacturing Partner

Leverage our engineering expertise from concept to production:

- Design-for-Manufacturing (DFM) support

- Process optimization & defect prevention

- End-to-end project co-development

Engineered for your success – from prototype to mass production.

Precision CNC Machining Services

Beyond Die Casting – Complete Precision Manufacturing

We deliver high-tolerance CNC machining for complex geometries, complementing our die castings to meet your most demanding dimensional specifications.

Micron-Level Accuracy

Equipped with advanced CNC technology, we consistently achieve ±0.01mm tolerances – ensuring flawless fit and function for critical components.

Agile Custom Manufacturing

Specializing in high-mix, low-to-medium volume production, we adapt quickly to your unique requirements without compromising precision or quality.

Premium Surface Finishing Solutions for Die Castings

In-House Matte Finishing

Achieve uniform matte surfaces through our integrated shot blasting and chemical cleaning processes – ideal for functional and aesthetic applications.

Performance-Enhanced Coatings

Anodizing: Superior corrosion protection

Powder Coating & Wet Painting: Durable color finishes

Branding & Customization

Laser engraving for permanent markings

Precision screen printing for logos/identification

One-Stop Finishing Services

Simplify your supply chain with our complete post-processing capabilities – from basic deburring to premium decorative finishes.

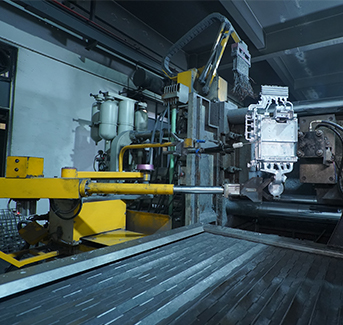

Precision Die Casting Production & Quality Assurance

Advanced equipment includes 180T to 1250T die casting machines, tooling & die equipment, automated mold temperature control systems, high-precision CNC machining centers, CMM and advanced metrology instrument. Leveraging state-of-the-art equipment and rigorous quality control, we deliver precision die cast components that consistently meet your exact specifications.

5 sets of EDM

4 sets of CNC machines

2 sets of Wire Cutting Machines

3 sets of Milling Machines

1 sets of High-speed Cutting Machines

2 sets of Grinder Machines

4 sets of Drilling Machines

2 sets of Lathing Machines

1 set of 1250-Ton HPM Cold Chamber Die Casting Machines

1 set of 800-Ton HPM Cold Chamber Die Casting Machines

1 set of 650-Ton HPM Cold Chamber Die Casting Machines

2 set of 400-Ton HPM Cold Chamber Die Casting Machines

3 set of 280-Ton HPM Cold Chamber Die Casting Machines

2 set of 180-Ton HPM Cold Chamber Die Casting Machines

2 sets of 5-axis CNC Machines

10 sets of 4-axis CNC Machines

15 sets of 3-axis CNC Machines

12 sets of CNC Lathes

Carl Zeiss CMM

Vision Measurement Systems

Keyence 3D Scanners

Spectrum Metal Analyzer

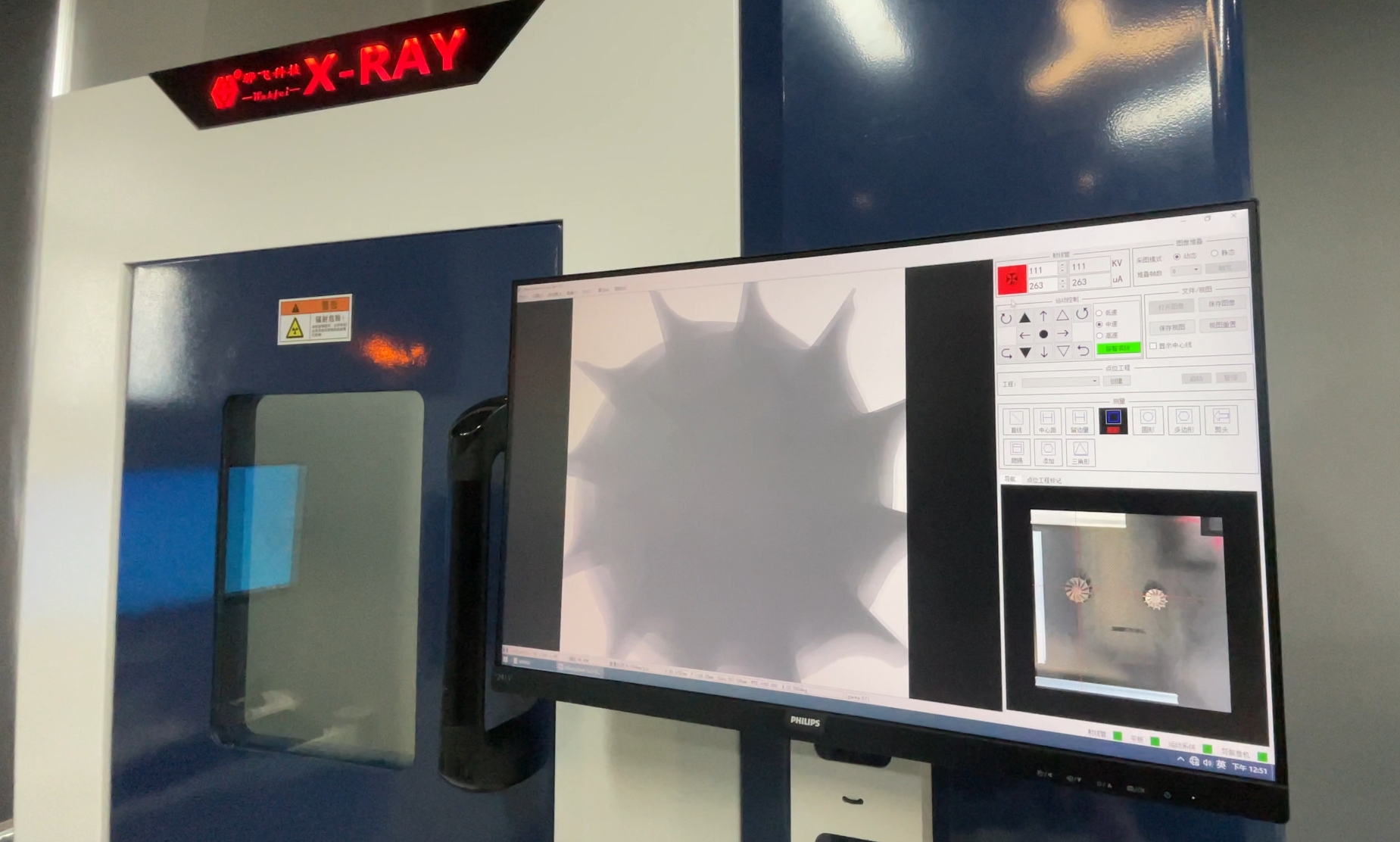

X-ray Detector

Cleanliness Test

Microscope

Pressure Leakage Test

Salt Spray Testing Equipment

Pneumatic Measuring Instrument

Hardness Testing Machine

Color Meter Machine

Thickness Testing Machine

Die Casting Engineering Support Services

Full-Cycle Project Expertise

Our engineering team partners with you from initial design through production, leveraging advanced CAE tools to optimize rapid prototyping, mold design and final part performance.

Advanced Engineering Capabilities

![]() Design Validation: Pro/Engineer & Pro/Manufacture integration for DFM (Design for Manufacturing)

Design Validation: Pro/Engineer & Pro/Manufacture integration for DFM (Design for Manufacturing)![]() Virtual Simulation: CAD/CAM file optimization in digital environments

Virtual Simulation: CAD/CAM file optimization in digital environments![]() Process Simulation: Mold flow, solidification, and cooling analysis to prevent defects

Process Simulation: Mold flow, solidification, and cooling analysis to prevent defects![]() Value Engineering: Cost-reduction strategies without compromising quality

Value Engineering: Cost-reduction strategies without compromising quality

Quality Assurance for Precision Die Castings

With certified quality systems, such as IATF 16949 automotive compliance, ISO 9001 certified processes, PPAP documentation support and 100% dimensional inspection, we guarantee: Zero-defect quality standards, On-time delivery performance and End-to-end technical support.

IATF 16949

ISO 13485

ISO 9001

ROHS & REACH

Precision Process Control for Die Cast Components

Our quality engineers rigorously monitor every production stage – from material certification to final shipment – ensuring consistent compliance with your specifications.

First Article Inspection (FAI)

100% dimensional verification using CMM

In-Process Quality Control (IPQC)

Real-time process parameter monitoring

X-Ray Defect Detection

Internal porosity analysis and digital defect mapping reports

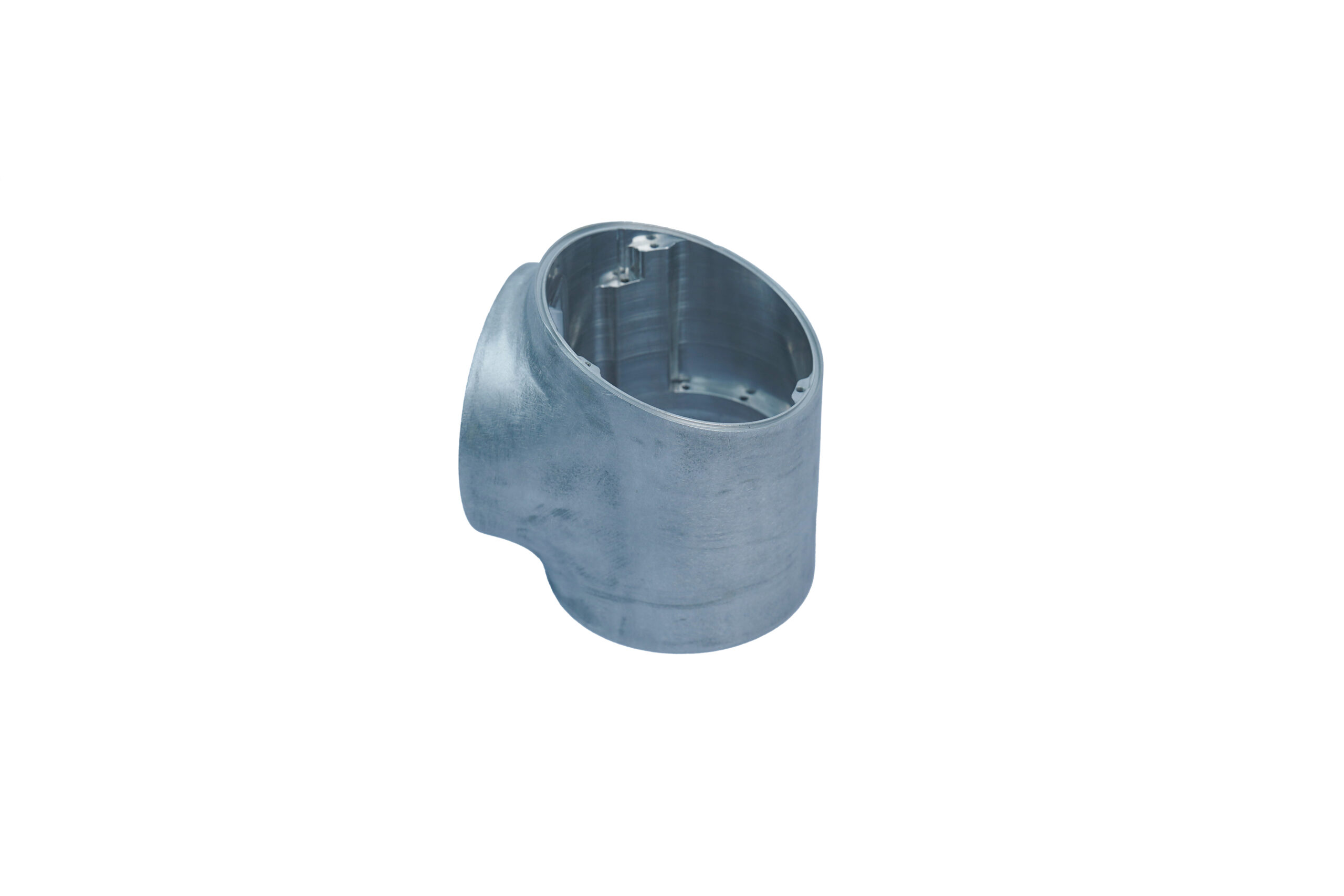

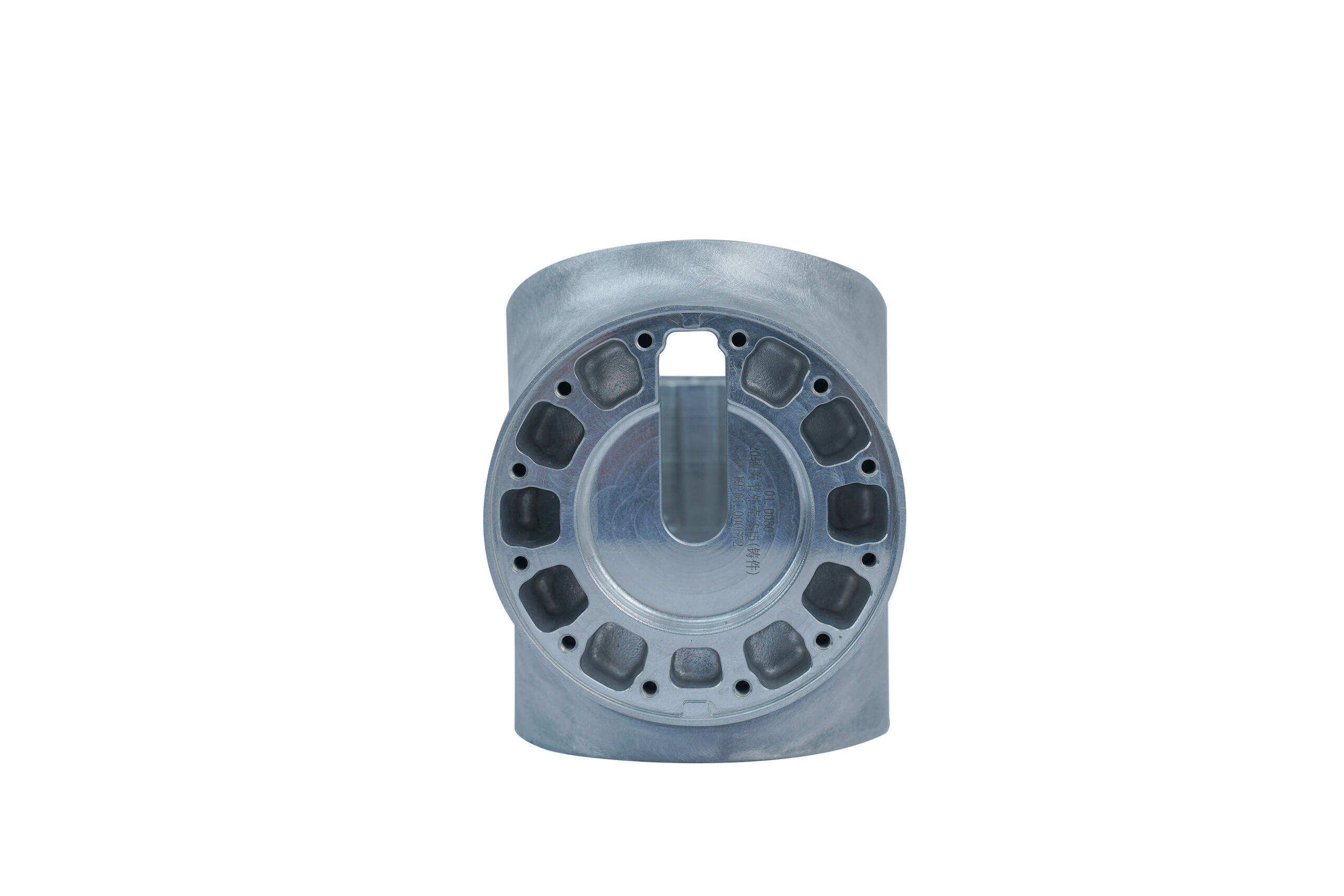

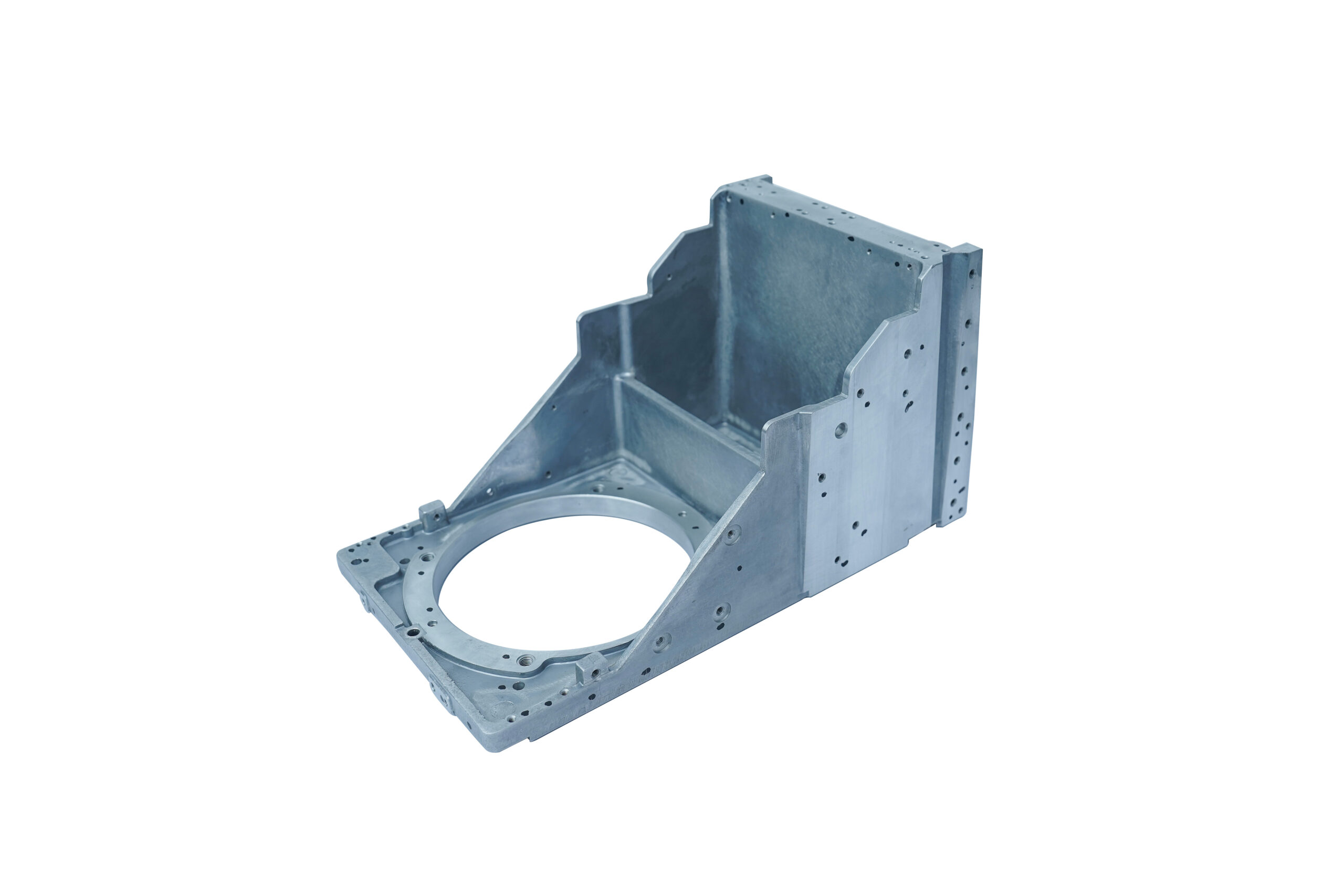

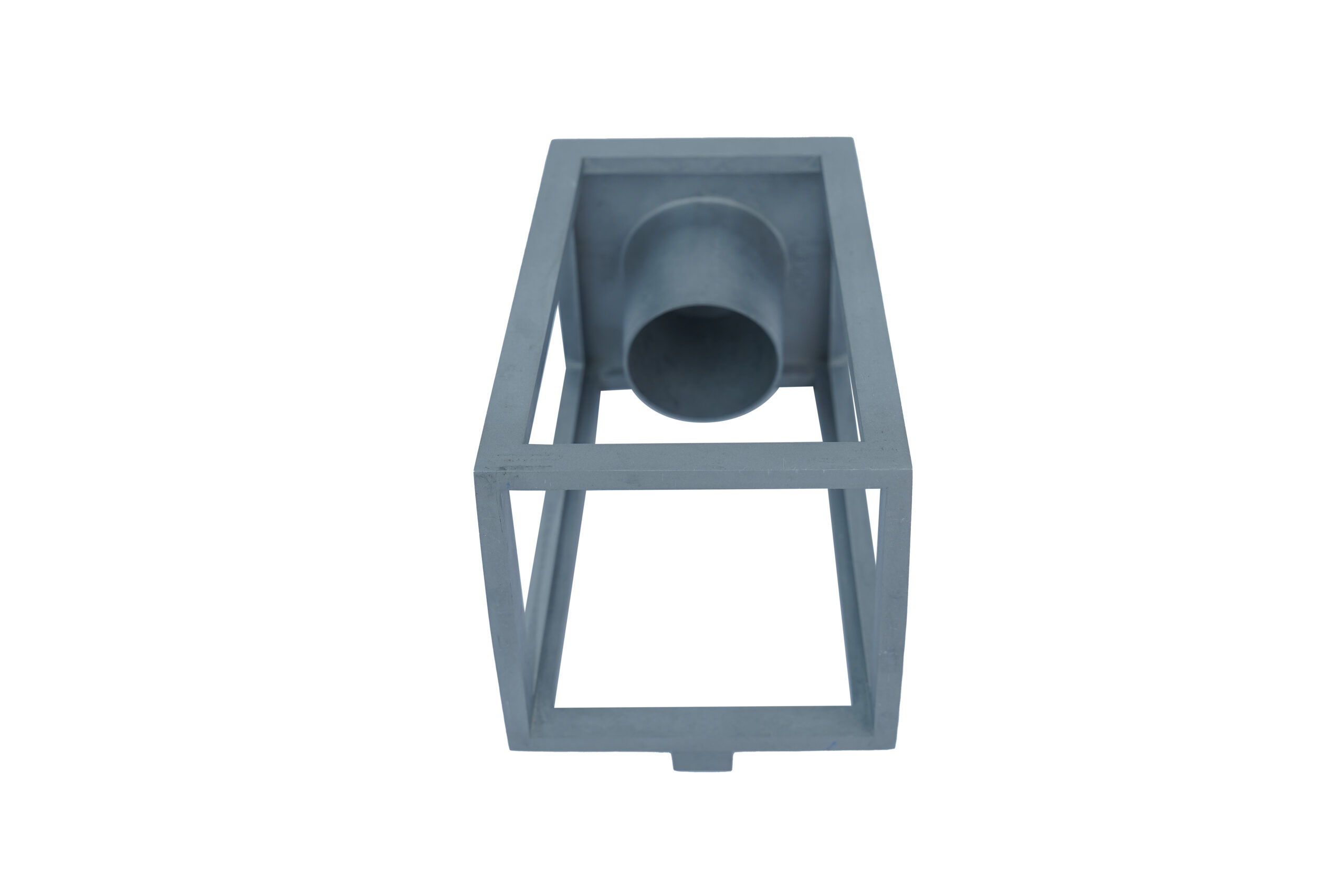

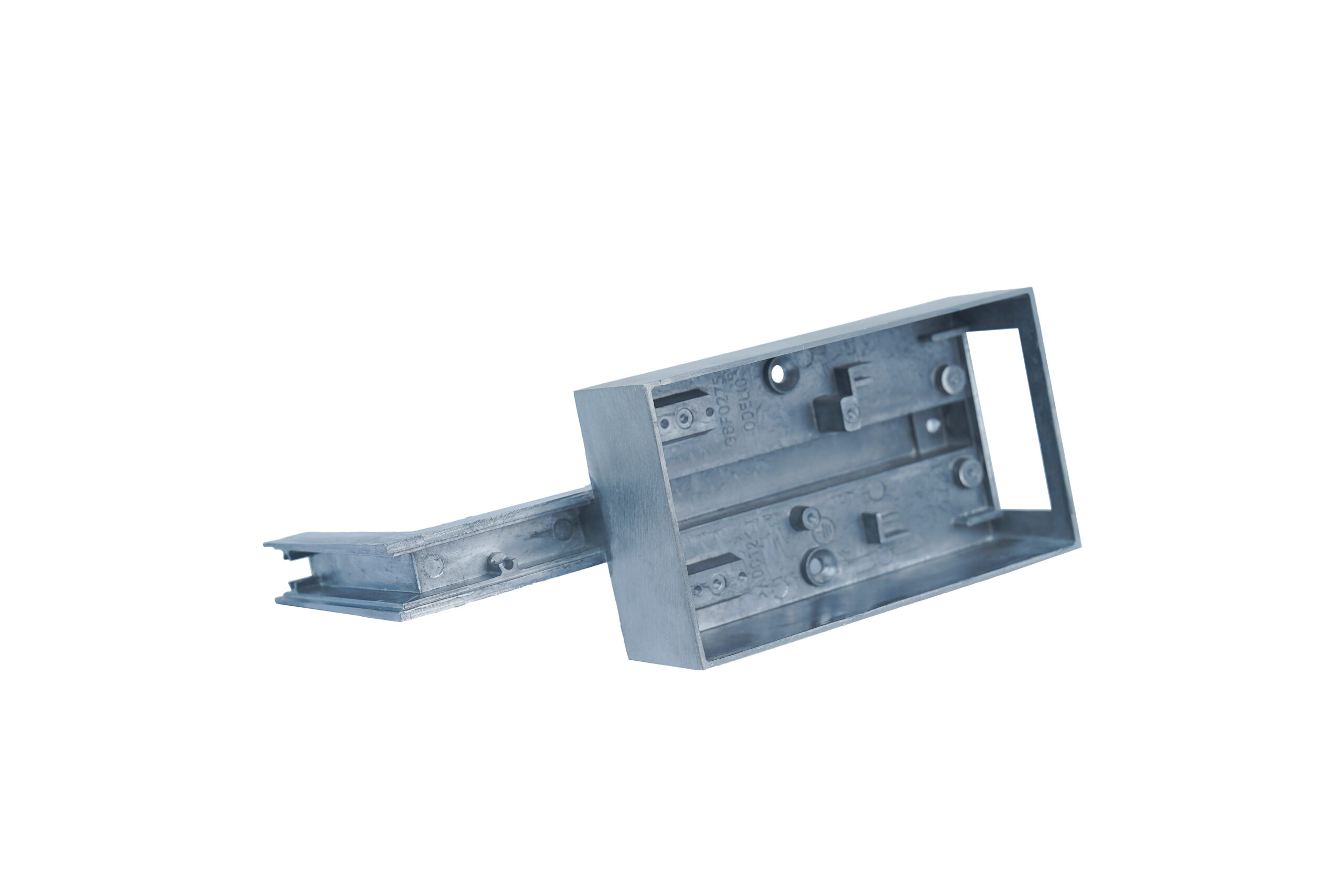

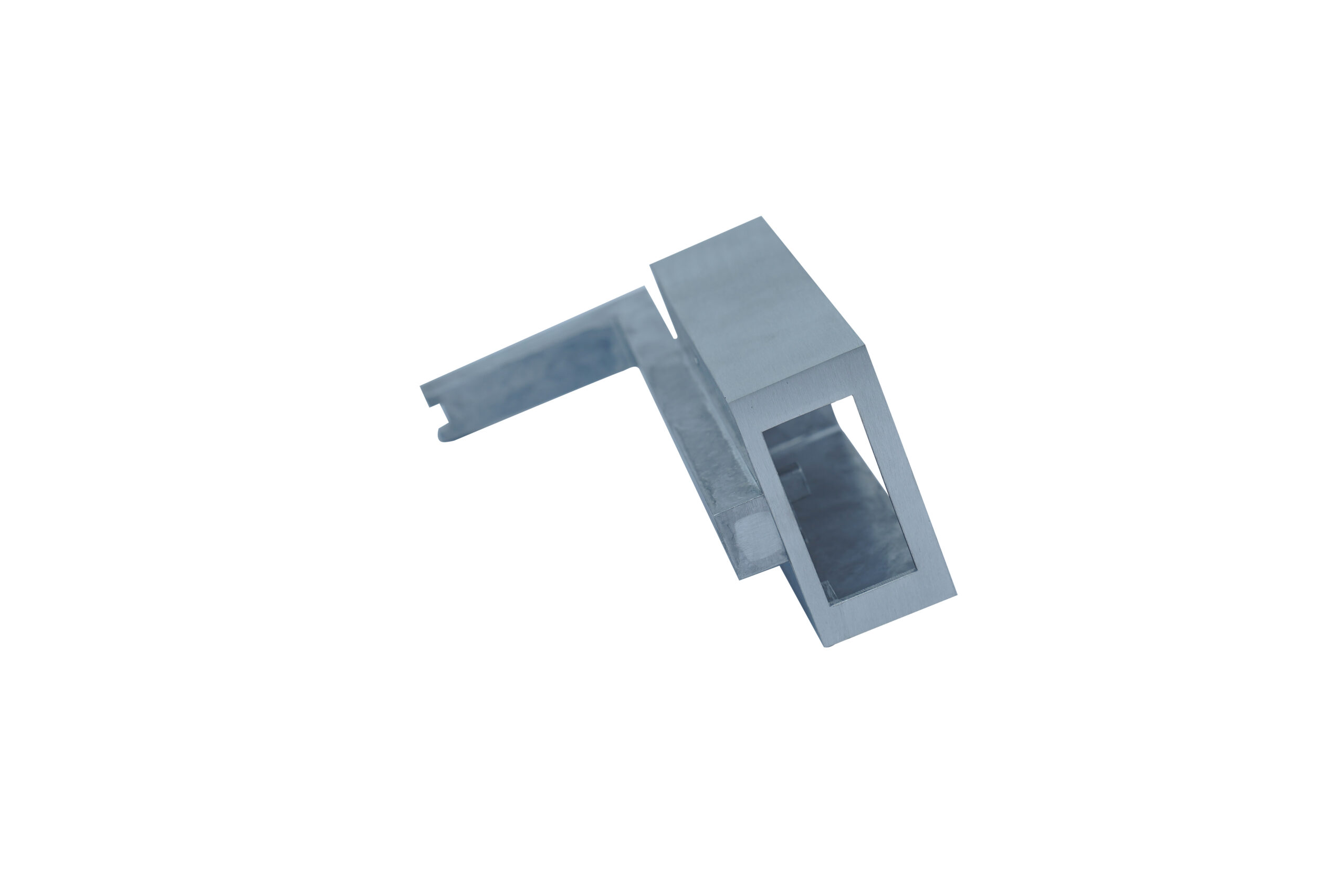

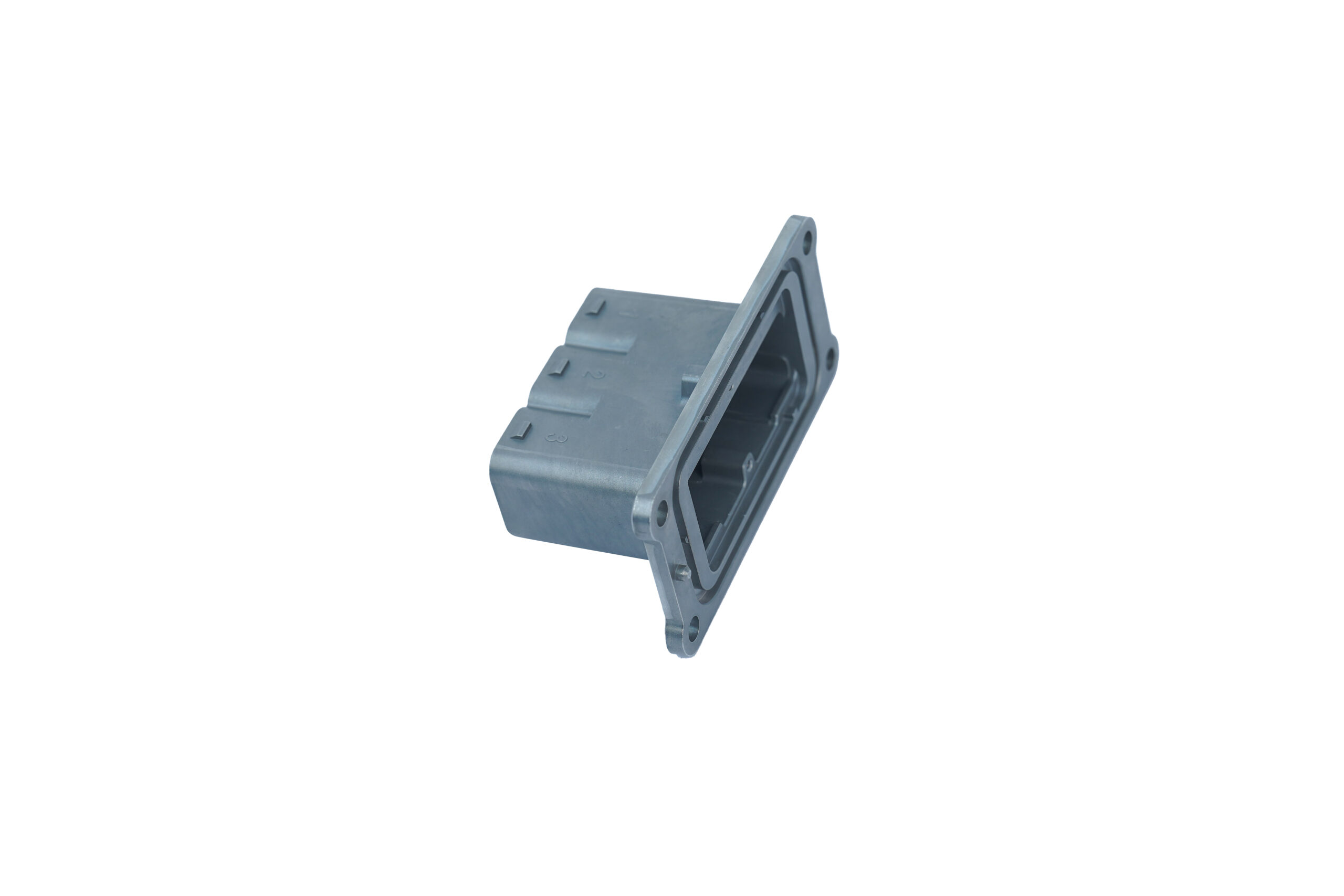

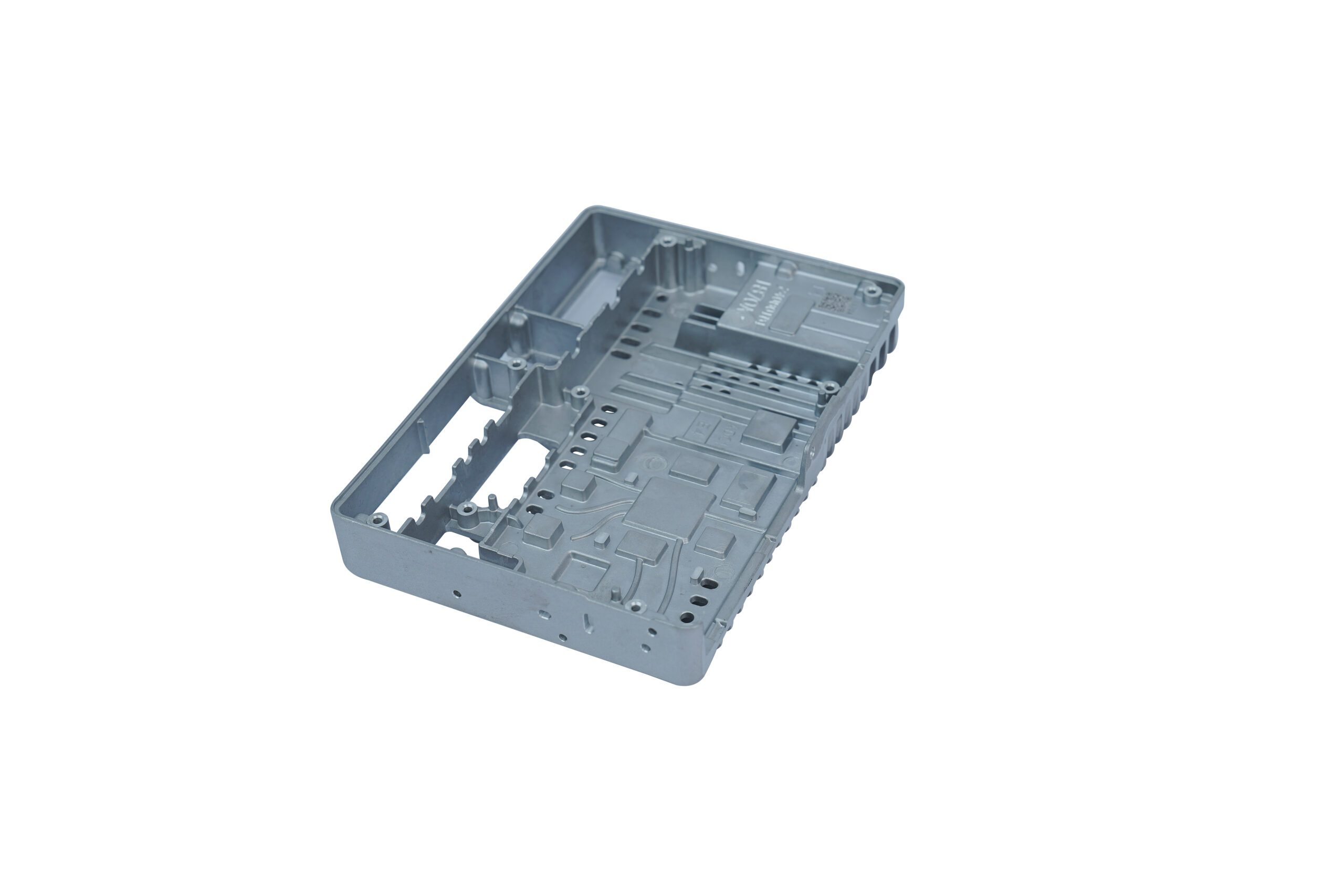

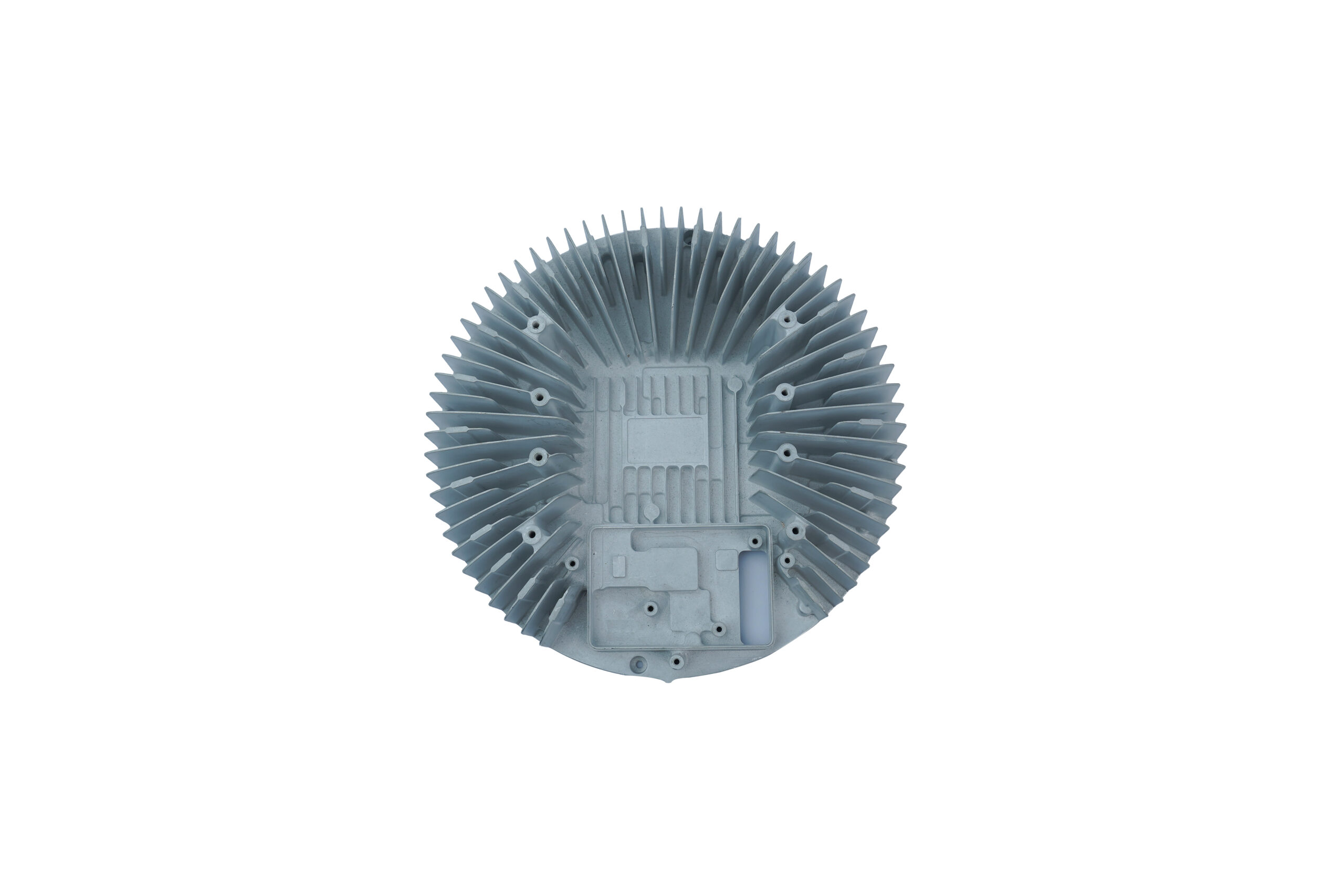

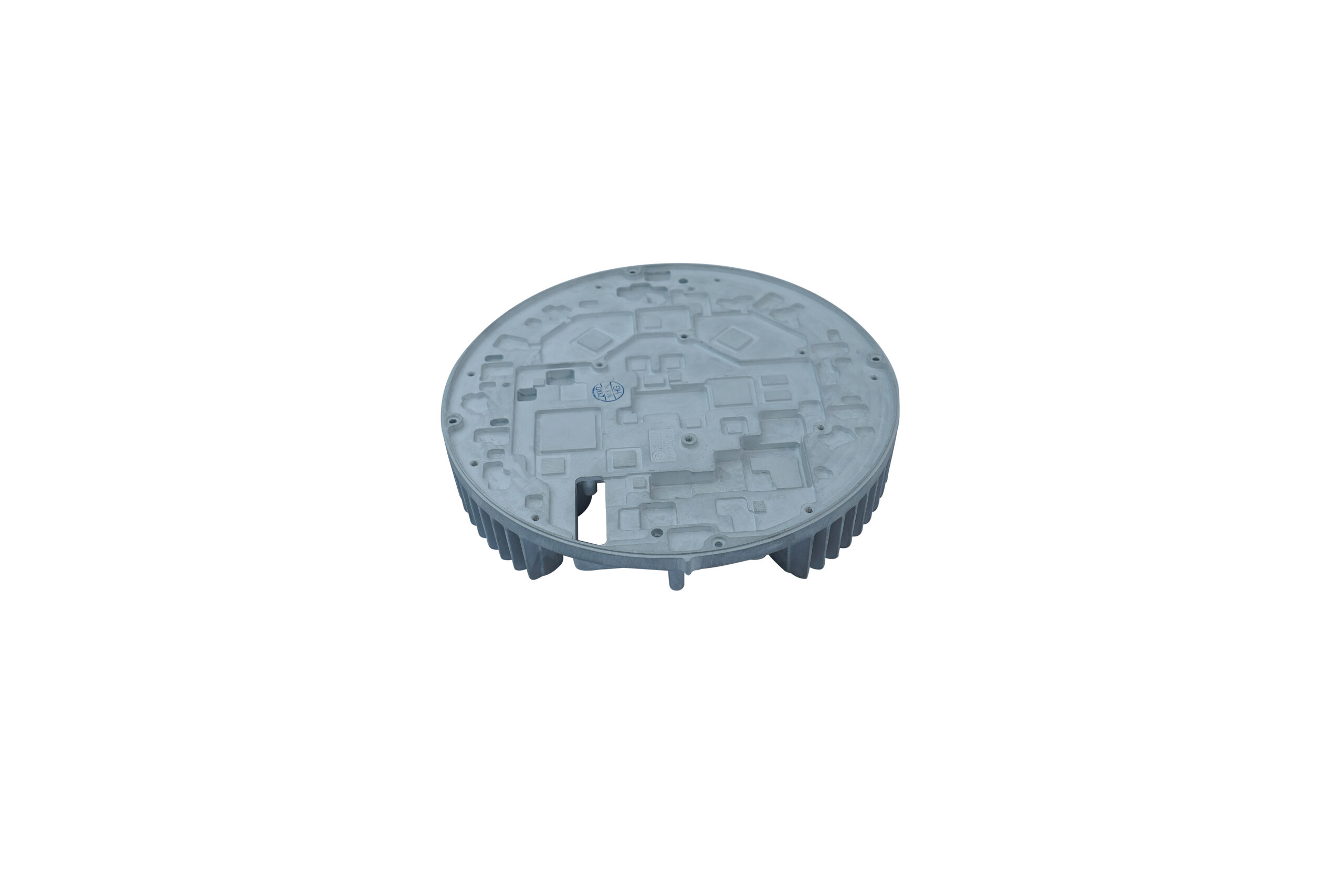

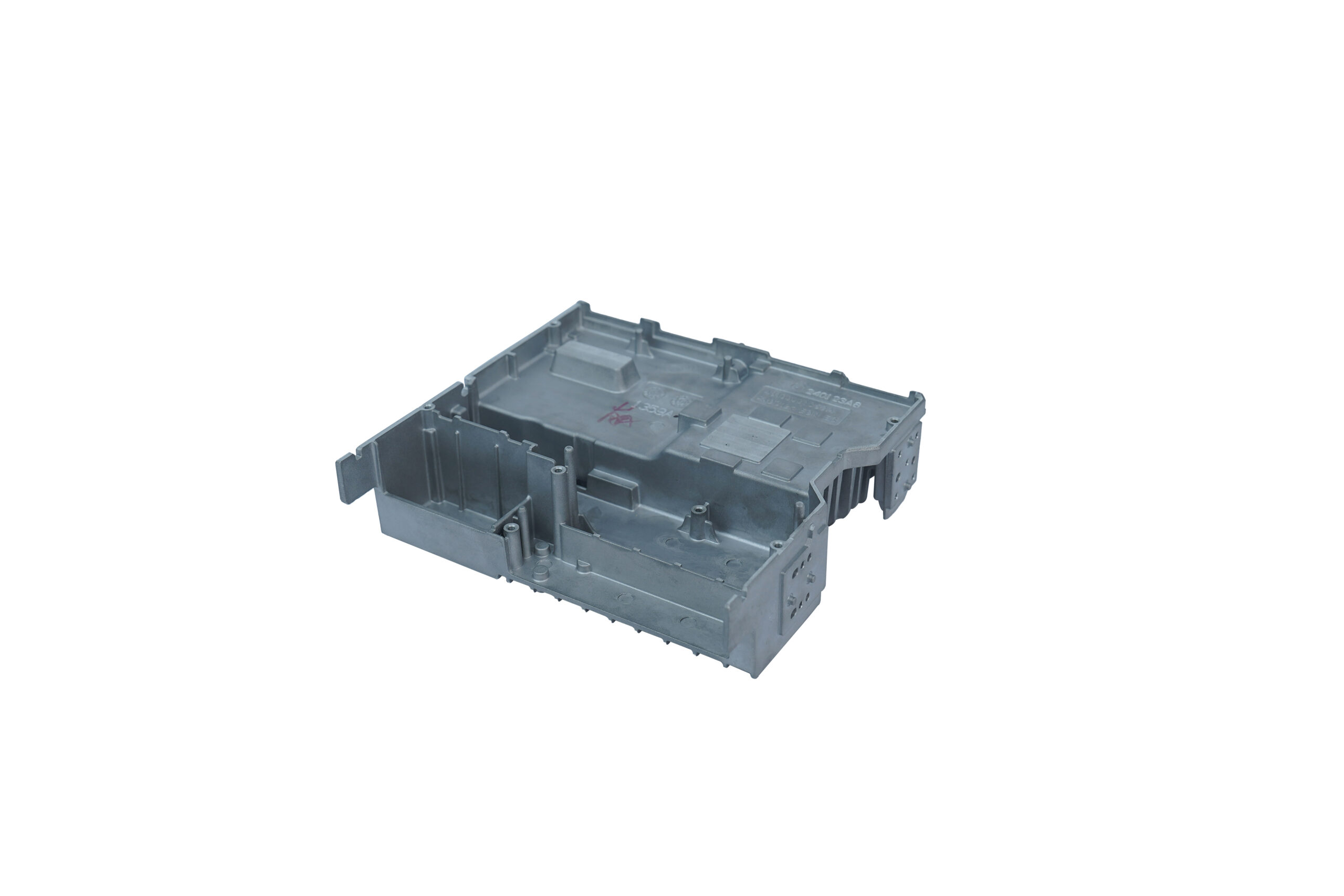

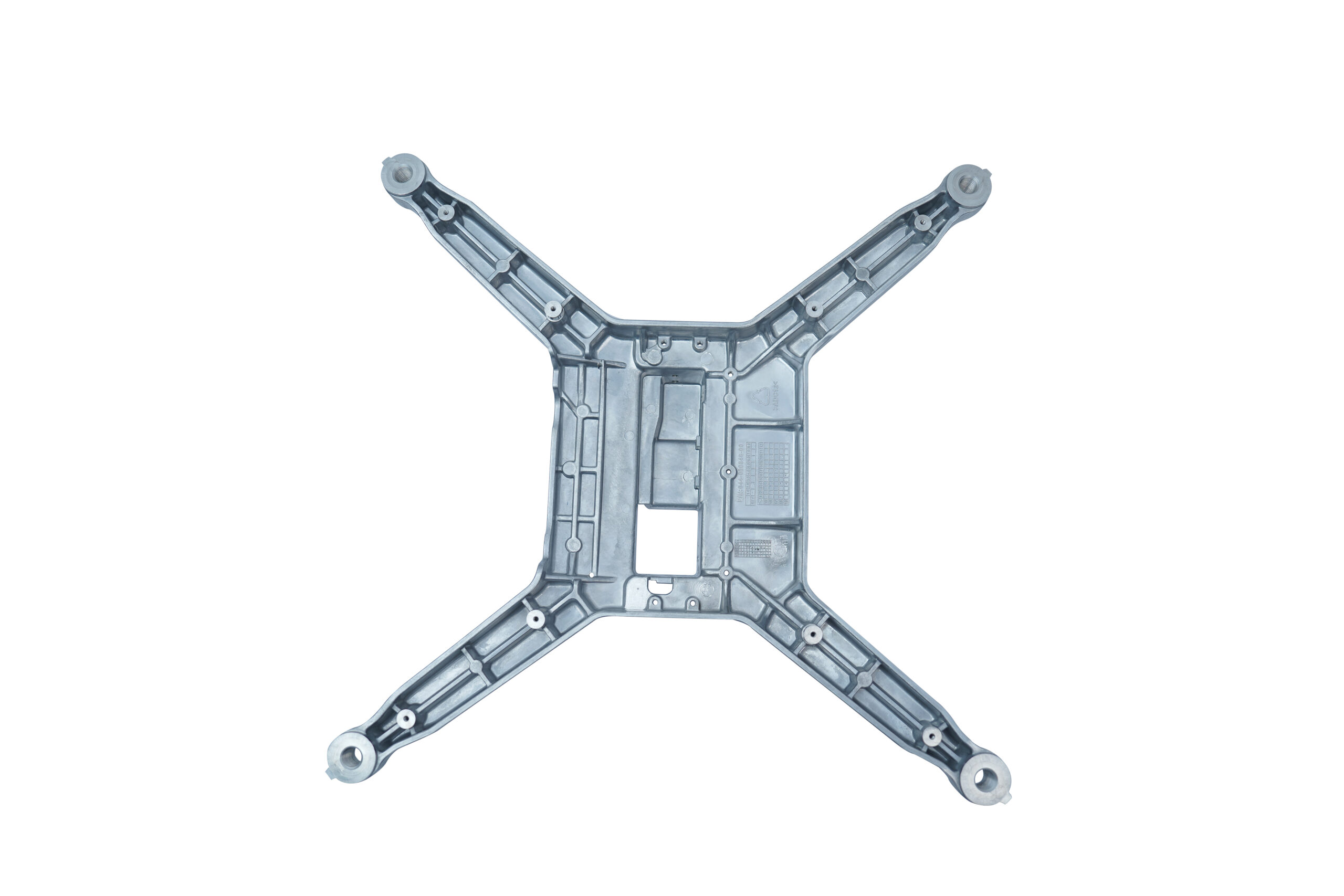

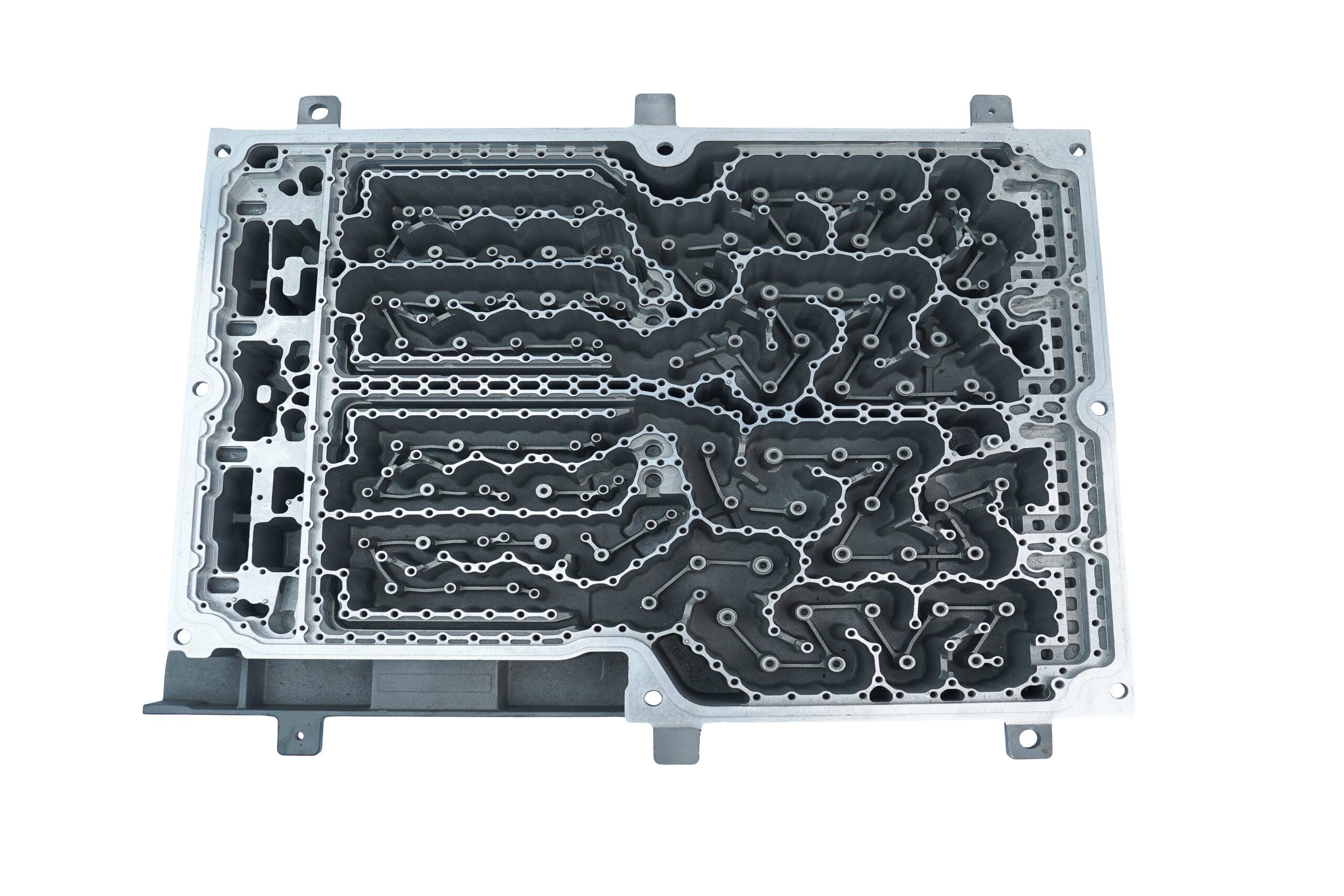

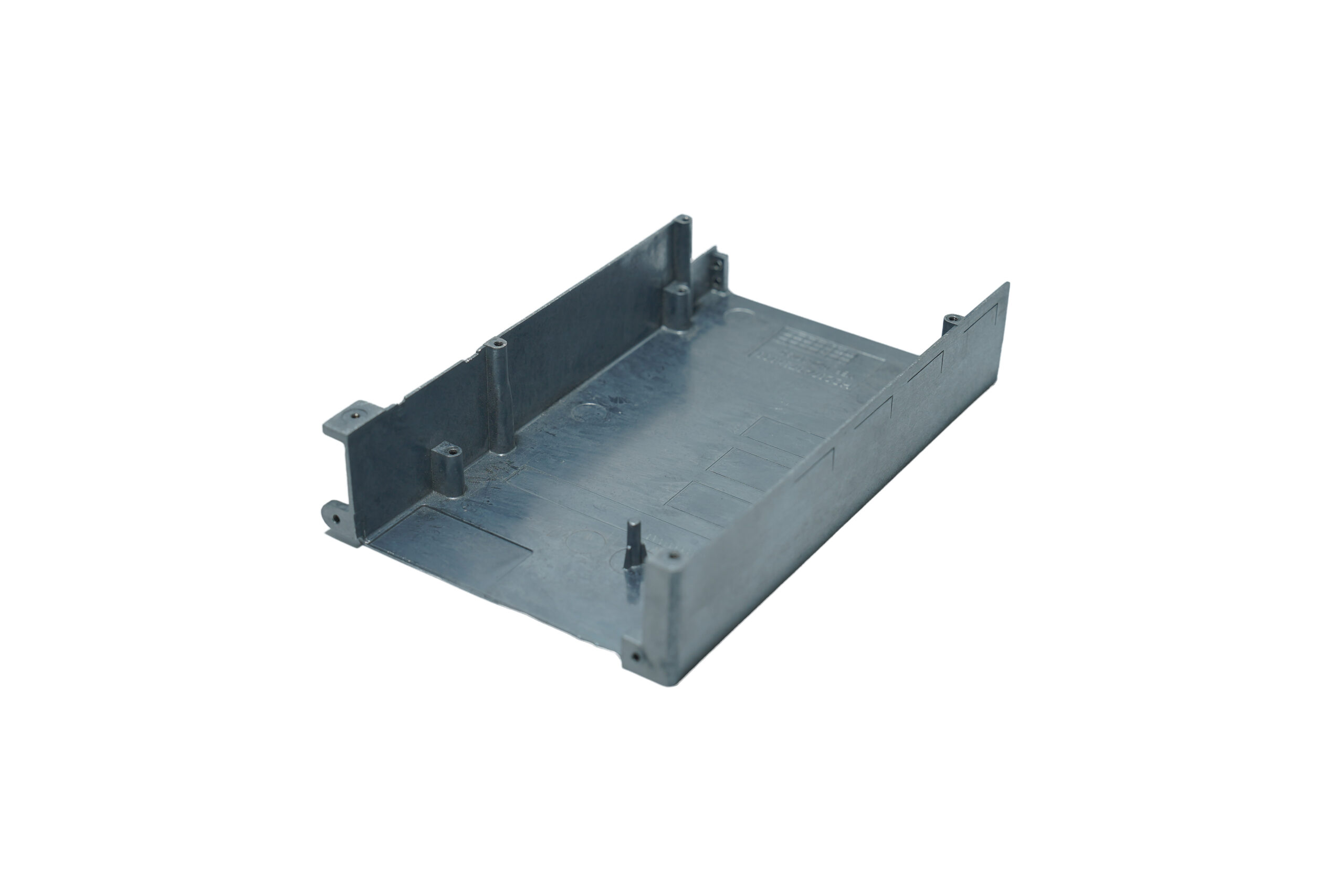

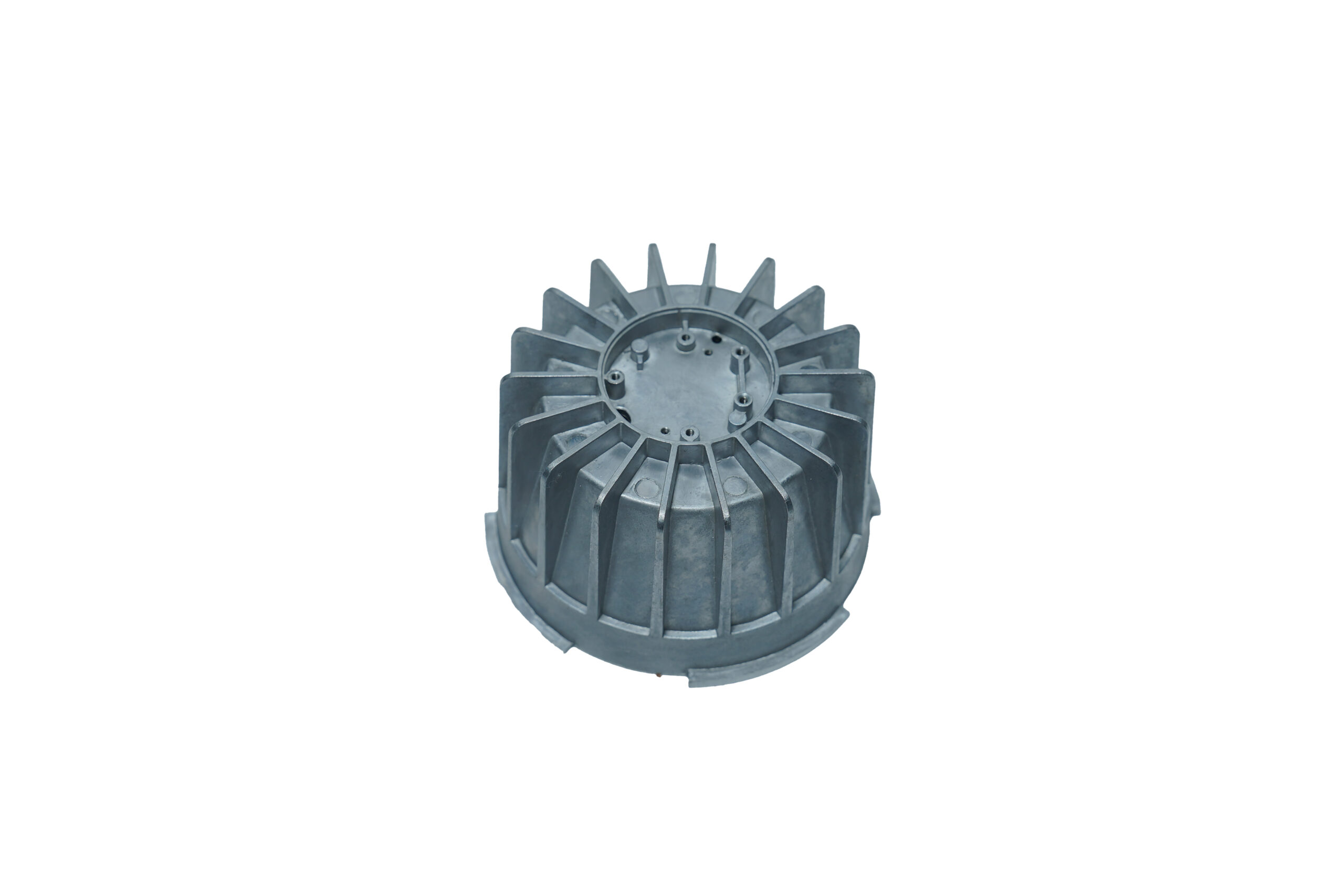

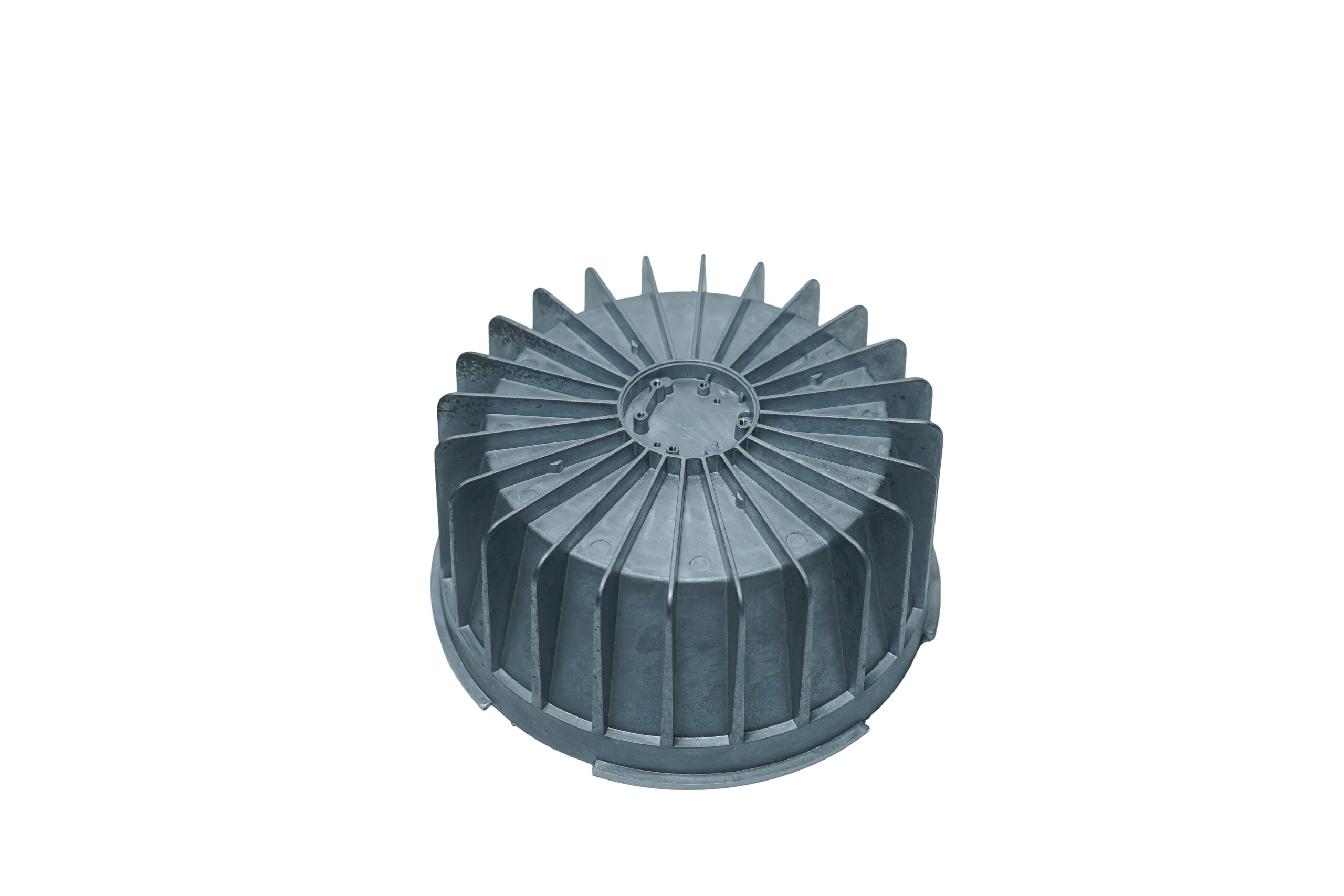

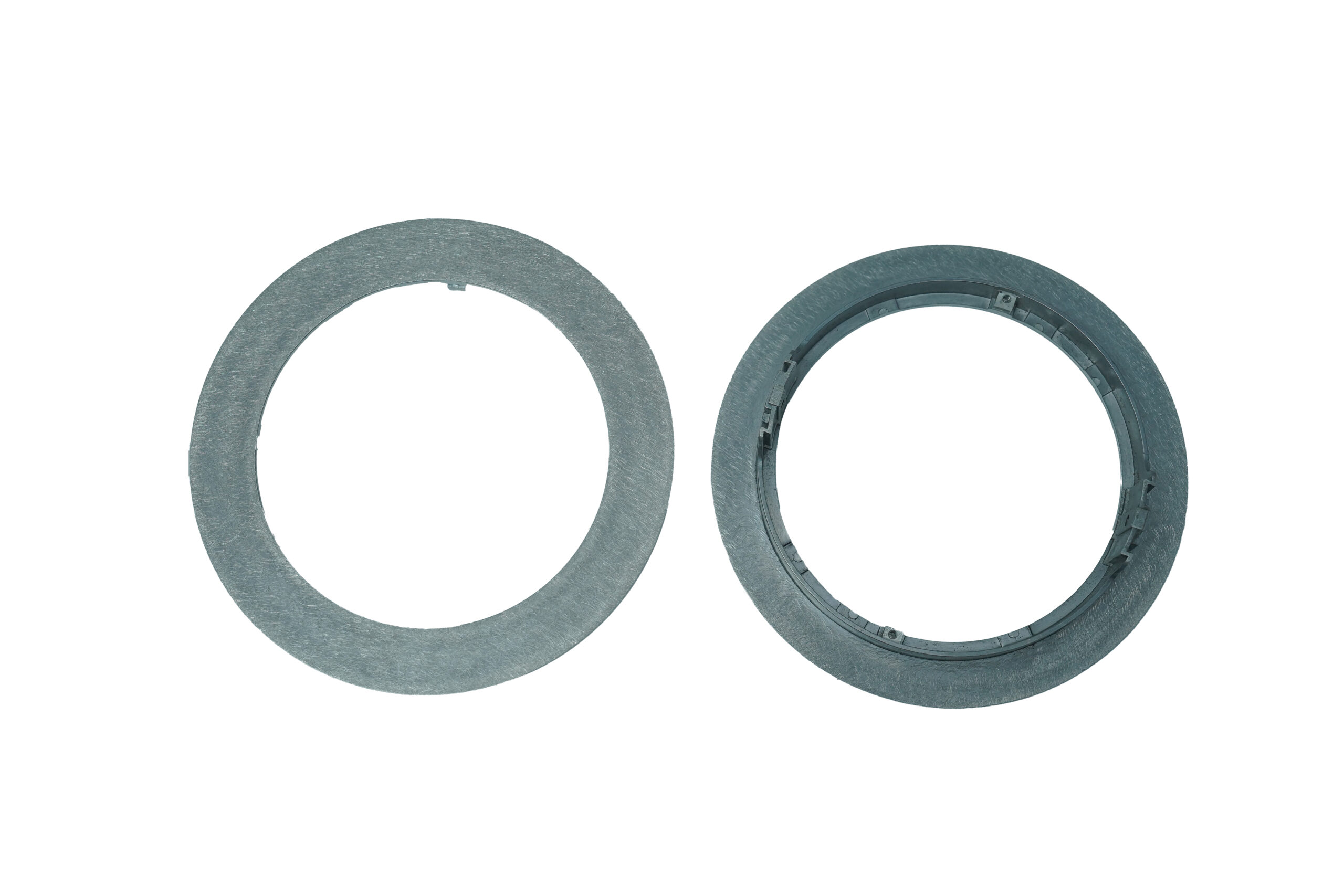

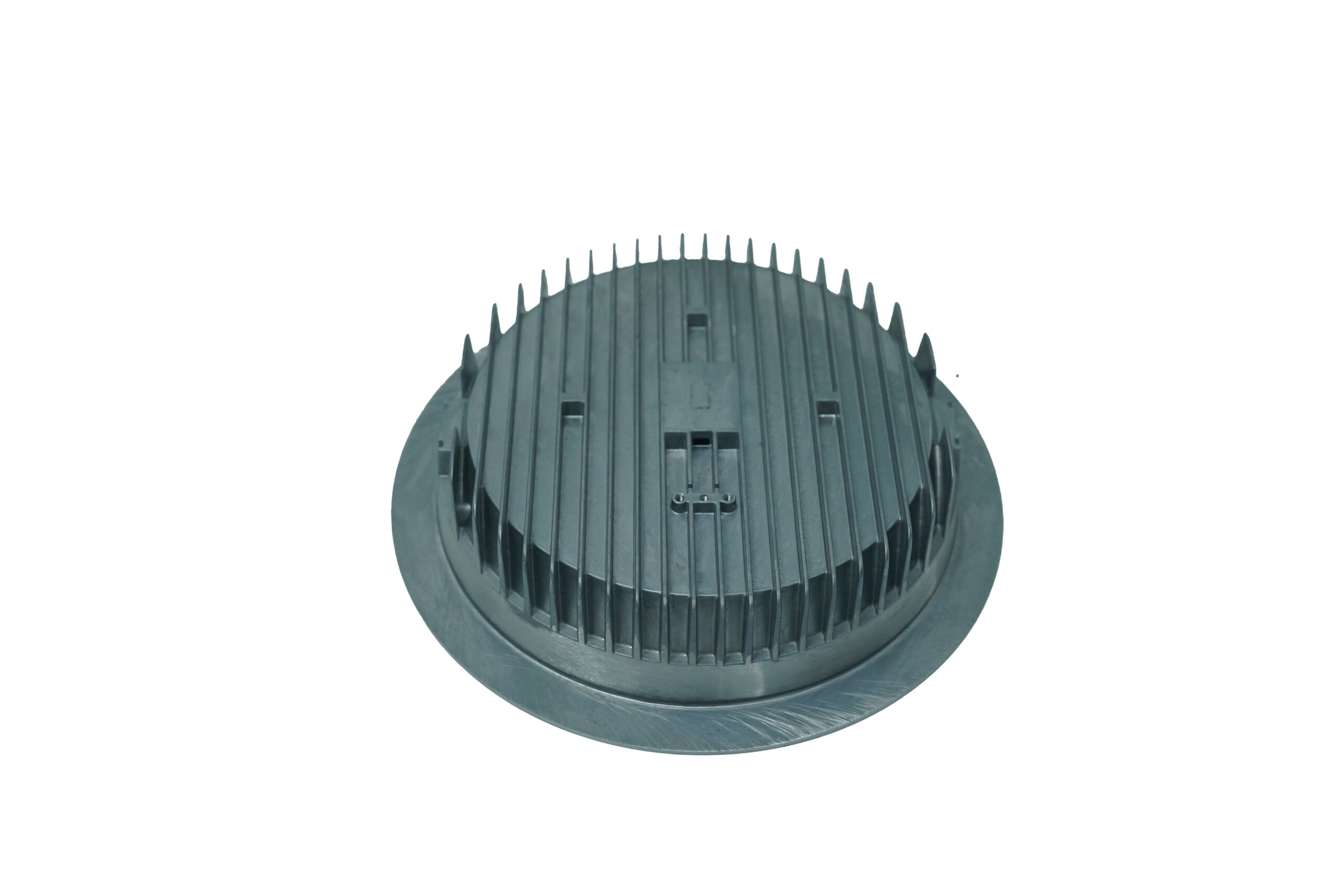

Die Casting Products Gallery

Whether you need small precision die castings or large complex parts, we have the expertise and capability to produce high quality products for different applications.

Customer-Driven Excellence-The Voice from Our Clients

At JUFENG Precision, client feedback fuels our continuous improvement – refining processes, enhancing product quality,

and elevating service standards to meet evolving industry demands.

Michael

Technical Buyer (USA)

We truly appreciate our partnership with JUFENG Precision. The quality and performance of your products have shown remarkable improvement, and we are confident that the coming year will be a successful one for both our companies. A special thanks to your team for driving cost reductions and ensuring on-time deliveries-your support has been great.

David

Project Engineer (UK)

JUFENG Precision consistently delivers excellence, whether for new projects or ongoing production parts. Their extensive expertise and strong support are highly beneficial. I particularly appreciate their outstanding DFM capabilities, rapid response, and reliable on-time delivery.

Marco

Mechanical Engineer & Technical Buyer (EU)

JUFENG Precision provides high-quality components that meet our specifications. We anticipate further strengthening our partnership in the coming year through expanded cooperation.

Who We Work With

We are looking forward to working with you and be your trustworthy & reliable partner in any die castings or CNC machining parts demands.

JUFENG Precision FAQ Guide

Looking for a reliable supplier for flexible-volume die casting production with cost-optimized solutions? JUFENG Precision specializes in high-quality die casting design and manufacturing, delivering one-stop solutions tailored to your project needs. From prototyping to mass production, we ensure precision, efficiency, and exceptional service for your die casting requirements.

Q: Do you provide custom die casting design services?

A: Yes, our expert engineering team offers full design support using advanced CAD/CAE tools to optimize your part for manufacturability, performance, and cost efficiency.

Q: Do you offer mold flow analysis for die casting optimization?

A: Yes. We perform advanced mold flow simulations to predict and resolve potential defects, ensuring smoother production and cost-effective die casting solutions.

Q: Do you offer PPAP documentation support?

A: Yes. We provide complete PPAP (Production Part Approval Process) support for die casting projects, including all required documentation and testing to ensure seamless customer approval.

Q: What is your quality control process for die casting production?

A: We maintain IATF 16949-certified quality systems with rigorous process controls, including:

Real-time production monitoring

Dimensional inspections with CMM

Material and performance testing

This ensures consistent quality from mold design to final shipment.

Q: What is your parts traceability system?

A: We implement a strict traceability system where:

Each batch is documented with control cards

Every component receives a unique ID (labeling/printing/laser etching)

Full production data is archived for 10+ years

Ensuring complete traceability from material source to final delivery.

Q: How do you implement continuous improvement in your operations?

A: Through our Kaizen-based improvement system, we:

• Conduct regular PDCA cycles for process optimization

• Invest in advanced die casting technologies

• Implement customer feedback-driven enhancements

This structured approach ensures year-over-year quality and efficiency gains.