Automotive Die Casting Components

At JUFENG Precision, we specialize in high-pressure die casting (HPDC) of premium aluminum automotive components, delivering unmatched strength, durability, and lightweight efficiency for modern vehicles. Our advanced die-cast cockpit system parts are engineered to enhance structural integrity, safety, and design flexibility in automotive applications.

Partner with JUFENG Precision for high-quality, precision-engineered automotive die casting solutions that drive innovation.

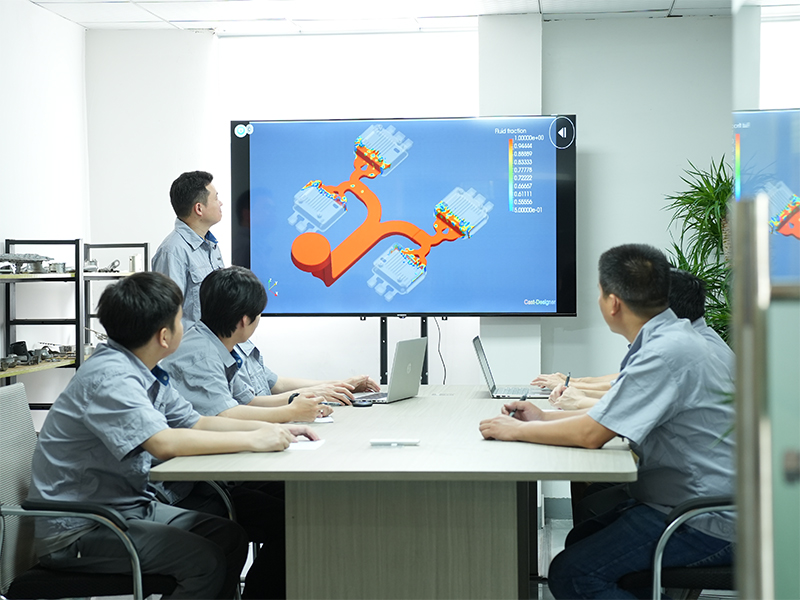

Automotive Die Casting Manufacturing Capability at JUFENG Precision

Automotive aluminum die-cast components are manufactured using advanced machinery and precision tooling, enabling rapid production cycles. JUFENG Precision has established itself as a trusted manufacturer in both commercial and private sectors by consistently delivering high-quality automotive aluminum castings.

DFM discuss & review

Material quality control

Die casting process

CNC machining process

Surface finishing process

Dimension inspection

Advanced Equipment for Aluminum Die Casting

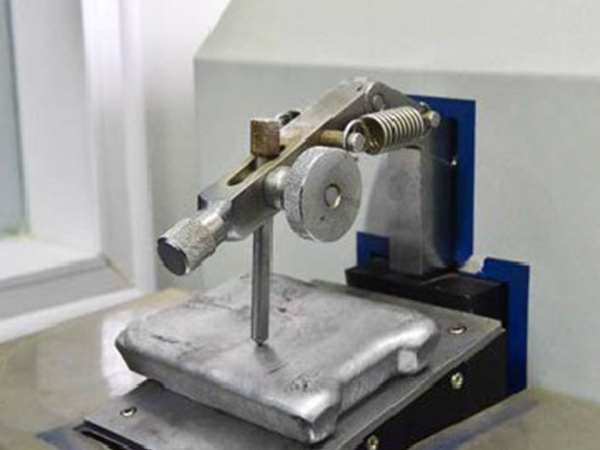

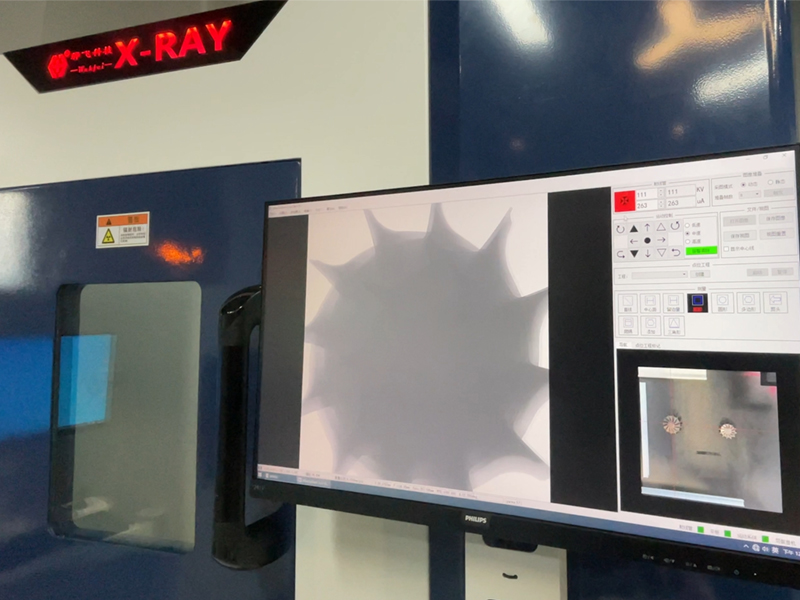

X-ray instrument

Aluminum die casting machine

Die casting parts inspection

CNC machining machine

Laser etching machine

CMM instrument

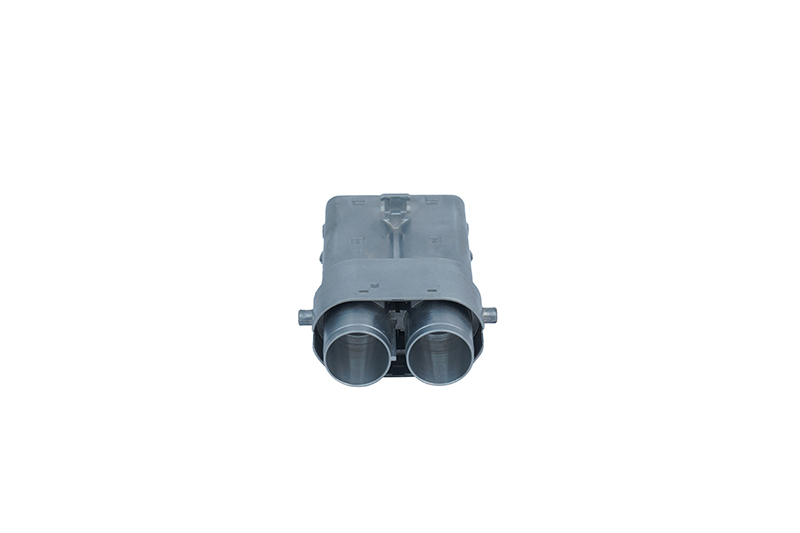

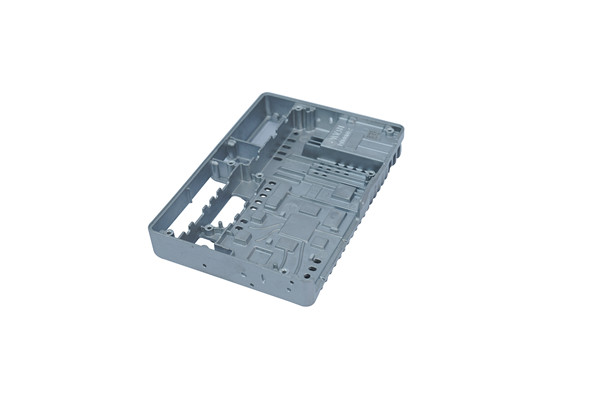

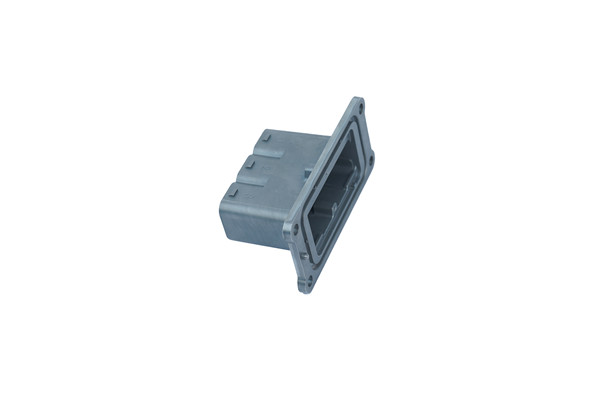

Recent Automotive Aluminum Die Casting Projects

Part Name:

Material:

Size:

Weight:

Machine Tonnage:

Surface Finish:

Production Process:

Applied Industry:

Automotive Die-Cast FAQ Guide

Die-Cast Automotive Components: Lightweight, Durable & Cost-Efficient

In the automotive industry, high-performance die-cast parts are increasingly favored for their superior strength-to-weight ratio and production scalability. As a trusted die-casting specialist, JUFENG Precision ensures compliance with global standards (e.g., IATF 16949) through:

Premium Alloy Selection: ADC12, A380, and custom aluminum alloys for optimal mechanical properties.

Advanced Die-Casting Systems: High-pressure die-casting (HPDC) machines with real-time monitoring for precision.

Which Die Cast Products Are Made for the Automotive Sector?

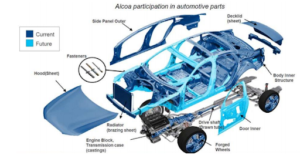

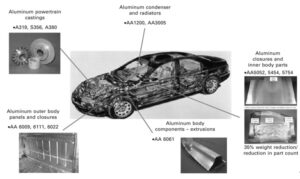

The automotive industry is increasingly adopting high-pressure die-cast (HPDC) aluminum components to meet stringent fuel efficiency and emission standards. Lightweight yet durable, these precision-cast parts help reduce vehicle weight, lowering fuel consumption and CO₂ emissions while maintaining structural integrity.

Why Aluminum Die Casting Dominates Automotive Manufacturing

As automakers transition from steel to aluminum, die casting offers unmatched advantages:

✔ Thin-Wall Capability – Enables complex, lightweight designs without sacrificing strength.

✔ High Mechanical Performance – Delivers superior durability under stress and thermal loads.

✔ Cost-Effective Production – Near-net-shape casting minimizes machining and material waste.

Key Automotive Die Cast Components

In automotive industry, high-precision die-cast parts for next-gen vehicles, including:

Engine & Powertrain

✓ Engine blocks & cylinder heads

✓ Transmission housings & gearbox covers

✓ Turbocharger housings

Electric Vehicle (EV) Systems

✓ Motor stators & housings

✓ Battery enclosures & cooling plates

✓ Brackets for electric motors

Structural & Functional Parts

✓ Steering knuckles & suspension components

✓ Heat sinks for thermal management

✓ Lightweight chassis reinforcements

JUFENG Precision: Your Trusted Die-Casting Partner

Our IATF 16949-certified facilities produce automotive-grade die castings with:

- Tight tolerances (ISO CT6-CT7)

- Custom alloys (ADC12, A380, and specialty blends)

- Full-service support from design to delivery

Upgrade your automotive components with precision die casting—contact us now!

What Are the Advantages of Aluminum Automotive Castings?

Aluminum die-cast components have become indispensable in modern automotive manufacturing, offering a winning combination of performance, efficiency, and cost-effectiveness. Here’s why leading automakers increasingly rely on aluminum die casting:

- Lightweight = Fuel Efficiency + Performance

- Reducing vehicle weight by 15% can improve fuel efficiency by up to 25%

- Aluminum castings weigh ~60% less than steel while maintaining strength

- Critical applications: engine blocks, wheel hubs, suspension components

- Enables compliance with stringent global emission standards (Euro 7, CAFE)

- High-Pressure Die Casting (HPDC) Advantages

✔ Mass Production Capability

- Automated HPDC systems produce 500-1,000 parts/day per machine

- Near-net-shape forming reduces post-processing by up to 40%

✔ Superior Material Properties

- Dimensional stability: Maintains high precision

- Heat resistance: Withstands operating temps up to 250°C

- Corrosion resistance: Ideal for under-hood components

- Manufacturing Excellence

✔ The HPDC Process Flow:

- Tooling Design – CAD/CAM-optimized molds

- Alloy Preparation – ADC12, A380, or custom aluminum blends

- Injection – 600-1,200 tons of clamping force

- Quality Control – X-ray inspection, CMM verification

✔ Alternative Processes:

- Squeeze casting for ultra-dense components

- Vacuum die casting for porosity-critical parts

Why Choose JUFENG Precision for Your Automotive Castings?

- IATF 16949-certified production

- Thin-wall capabilities down to 2.5mm

- Full-service support from prototyping to mass production

Contact us to discuss your aluminum die casting needs.

What Is High Pressure Die Casting (HPDC)?

High Pressure Die Casting (HPDC) is the premier manufacturing process for producing high-volume, precision aluminum components, particularly for the automotive industry. This advanced metal forming technique delivers exceptional part quality through:

Key Process Characteristics:

- High-Speed Production: Molten aluminum (typically ADC12 or A380 alloys) is injected into steel molds at pressures ranging from 1,500 to 25,000 psi.

- Superior Part Quality: Produces components with:

- Minimal porosity (<1% in optimized processes)

- Excellent surface finish (Ra 1.6-3.2 μm achievable)

- Tight tolerances (ISO CT6-CT7 standard)

Why HPDC Dominates Automotive Manufacturing:

- Complex Geometries: Capable of producing intricate, thin-walled components (as thin as 2.0mm)

- Reduced Assembly Needs: Enables consolidation of multiple parts into single castings

- Material Efficiency: Near-net-shape casting minimizes machining waste

The HPDC Cycle:

- Clamping: Die halves are securely locked (400-4,000 tons force)

- Injection: Molten metal is forced into the cavity (<0.1 second fill time)

- Cooling: Rapid solidification under pressure

- Ejection: Finished part is removed automatically

Industry Applications:

- Engine blocks and transmission cases

- Structural components (crossbeams, shock towers)

- EV battery housings and motor components

With cycle times as fast as 30 seconds, HPDC offers unmatched productivity for high-volume production while maintaining exceptional dimensional accuracy and mechanical properties. Modern HPDC systems incorporate real-time monitoring and AI-driven process optimization to ensure consistent quality.

Which Die Cast Materials Are Used for Automotive?

The automotive industry relies on high-performance die cast materials to meet demands for lightweight, durable, and cost-effective components. While several metals are suitable for die casting, aluminum dominates the market due to its exceptional balance of properties. Below we examine the key materials used in automotive die casting applications.

- Aluminum – The Industry Standard

Why it’s preferred:

✔ Lightweight – Reduces vehicle weight by up to 50% compared to steel, improving fuel efficiency

✔ High Strength-to-Weight Ratio – Maintains structural integrity under stress

✔ Corrosion Resistant – Ideal for under-hood and exterior components

✔ Recyclable – Sustainable and cost-efficient for high-volume production

Common Alloys:

- ADC12 (A383) – Excellent fluidity, ideal for thin-walled parts

- A380 – Superior mechanical properties for structural components

- A356 (T6 heat-treated) – High strength for safety-critical parts

Applications: Engine blocks, transmission housings, EV battery enclosures, suspension components

- Zinc – Precision & Surface Finish

Key Benefits:

✔ Easiest to Cast – Excellent fluidity for complex geometries

✔ High Dimensional Stability – Minimal post-casting machining required

✔ Superior Corrosion Resistance – Perfect for exterior trim and decorative parts

✔ Cost-Effective – Lower melting point reduces energy consumption

Common Alloys:

- Zamak 3 (most widely used)

- Zamak 5 (higher strength)

Applications: Door handles, brackets, sensor housings, interior components

- Magnesium – The Lightest Option

Advantages:

✔ Lightest Structural Metal – 33% lighter than aluminum

✔ Excellent Damping Properties – Reduces noise and vibration

✔ Good Machinability – Easy to process post-casting

Challenges: Higher cost and flammability risk during processing

Applications: Steering wheels, seat frames, gearbox cases

Why JUFENG Precision Prefers Aluminum Die Casting

At JUFENG Precision, we specialize in high-pressure aluminum die casting (HPDC) because:

- Delivers the best balance of performance, cost, and manufacturability

- Compatible with high-volume automotive production

- Supports sustainability through closed-loop recycling

For your next automotive casting project, trust our expertise in aluminum die casting solutions—contact us now for a consultation!

What Are the Requirements for Producing Die Castings for Modern Automotive Components?

The automotive industry’s shift toward electrification and lightweight demands next-generation die casting solutions that combine precision engineering with advanced material science. Modern die cast components must meet stringent performance criteria while enabling mass production of complex parts.

Key Technical Requirements for Automotive Die Castings

- Material Performance

✔ High Strength-to-Weight Ratio

- Aluminum alloys (e.g., A380, ADC12) with yield strength ≥220 MPa

- Magnesium alloys for ultra-lightweight applications (e.g., steering columns)

✔ Thermal & Electrical Management

- Superior thermal conductivity for EV battery housings

- EMI/RFI shielding properties for sensitive electronics

- Precision Manufacturing Capabilities

✔ Thin-Wall Casting (as thin as 1.5–2.0mm) for weight reduction

✔ Tight Tolerances (ISO CT6-CT7) for assembly-critical components

✔ Near-Net-Shape Production to minimize machining

- EV-Specific Demands

✔ High-Purity Aluminum for battery trays (low iron content <0.15%)

✔ Cooling Channel Integration in motor housings

✔ Crash-Resistant Designs with optimized ductility

Advanced Die Casting Technologies Meeting These Needs

- High-Pressure Die Casting (HPDC) with 1,500+ ton clamping force

- Vacuum-Assisted Casting for reduced porosity in structural parts

- Squeeze Casting for enhanced mechanical properties

Why Modern Automotive Manufacturers Choose Advanced Die Casting

- 40–60% weight savings vs. steel components

- 15–25% cost reduction through part consolidation

- Compliance with IATF 16949 and OEM-specific standards

Contact us to discuss your automotive die casting project requirements.

What Are the Different Applications of Die Casting for the Automotive Sector?

Die casting has become a cornerstone technology in modern automotive manufacturing, enabling the production of high-performance components that meet today’s demanding standards for safety, efficiency, and sustainability. The versatility of die casting processes allows for diverse applications across vehicle systems.

Key Automotive Applications of Die Cast Components

- Structural & Safety Components

- Body-in-White Structures: High-strength aluminum die castings are revolutionizing vehicle frames, reducing weight while maintaining crash-worthiness

- Crash Management Systems: Energy-absorbing components with optimized ductility

- Suspension Components: Precision-cast knuckles and control arms that withstand dynamic loads

Technical Advantage:

Modern structural die castings achieve wall thicknesses as low as 2.0mm while meeting ISO 26262 safety standards.

- Powertrain Systems

- Engine Blocks & Transmission Housings: Complex geometries with integrated cooling channels

- EV Battery Enclosures: Lightweight designs with thermal management features

- Electric Motor Components: High-conductivity housings for improved efficiency

- Customized Solutions

✔ Design Flexibility:

- Enables part consolidation (reducing assembly components by 30-50%)

- Accommodates complex shapes with undercuts and thin walls

✔ Material Versatility:

- Aluminum alloys for lightweighting

- Zinc alloys for decorative trim

- Magnesium for ultra-light applications

✔ Surface Finish Options:

- As-cast (Ra 3.2 μm) to polished (Ra 0.4 μm)

- Ready-for-coating surfaces

How Do Aluminum Die-Cast Products Help Reduce Automobile Emissions and Increase Fuel Efficiency?

The automotive industry’s shift toward aluminum die-cast components represents a transformative solution for improving fuel efficiency and reducing emissions. Here’s how this advanced manufacturing approach delivers environmental and performance benefits:

The Weight-Efficiency Equation

- A 10-15% weight reduction in vehicle components can improve fuel efficiency by 6-8% (SAE International)

- Aluminum die castings are ~60% lighter than equivalent steel parts

- Every 100kg reduction decreases CO₂ emissions by 8.5g/km (European Aluminum Association)

Why Aluminum Die Casting Wins

✔ Material Advantages:

- High strength-to-weight ratio (A380 alloy: 320 MPa tensile strength)

- Excellent thermal conductivity for optimized engine performance

- 100% recyclability with no quality degradation

✔ Manufacturing Benefits:

- Near-net-shape production minimizes material waste

- Thin-wall capabilities (down to 1.5mm) for maximum weight savings

- Consistent dimensional accuracy (±0.2mm typical)

Key Applications Driving Efficiency

- Powertrain Systems: Engine blocks, transmission cases

- Structural Components: Crossbeams, shock towers

- EV Components: Battery housings, motor enclosures

Comparative Advantages Over Traditional Parts

| Feature | Aluminum Die Castings | Conventional Parts |

| Weight | 60% lighter | Heavy |

| Production Rate | 500-1,000 parts/day | Slower processes |

| Dimensional Stability | ±0.2mm tolerance | Less precise |

| Corrosion Resistance | Excellent | Requires treatment |

Our Sustainable Solutions

Our IATF 16949-certified facilities specialize in high-performance aluminum die castings that help automakers:

- Meet Euro 7 and CAFE emissions standards

- Achieve 15-25% better fuel economy

- Reduce life cycle environmental impact

Contact us to optimize your components for efficiency

What Costs Need to Be Considered for Automotive Die Casting Components?

When budgeting for automotive die cast parts, several key cost factors must be evaluated:

- Material Costs

- Aluminum alloys (ADC12, A380) typically cost 2.50−2.50−3.50/kg

- Specialty alloys or high-purity variants add 15-30% premium

- Recycled material can reduce costs by 20%

- Part Complexity

✔ Wall Thickness:

- Standard (2.5-4mm) vs thin-wall (<2mm) designs affect material use

- Each 0.5mm reduction saves 3-5% in material costs

✔ Projected Area:

- Larger parts require bigger machines (higher hourly rates)

- Tooling costs increase exponentially with size

- Precision Requirements

- Standard tolerances (ISO CT7): $

- Tight tolerances (ISO CT6): $$ (+15-25%)

- Critical surfaces requiring machining: $$$ (+30-50%)

- Production Volume

| Quantity | Cost/Unit |

| Prototype (1-100) | Highest |

| Low-volume (1k-10k) | Medium |

| Mass production (50k+) | Lowest |

Cost-Saving Opportunities

- Design for Manufacturability (DFM) optimization

- Multi-cavity tooling for high volumes

- Standard alloy selection

Are There Limitations on Die Cast Parts for Automotive Applications?

While aluminum die casting dominates modern automotive manufacturing, certain technical and economic factors limit its universal adoption. Here are the key considerations:

- Material Property Constraints

Stiffness Requirements:

- Steel offers 3x higher modulus of elasticity (210 GPa) vs aluminum (70 GPa)

- Critical for chassis components and safety structures

- Solution: Hybrid designs combining die cast aluminum with steel reinforcements

- Economic Factors

Tooling Costs:

- High-pressure die casting molds require 50k−200k initial investment

- Only cost-effective for production runs >10,000 units

Material Costs:

- Aluminum prices fluctuate more than steel

- Secondary machining can add 15-30% to part cost

- Technical Limitations

Ductility Challenges:

- Standard die cast alloys have limited elongation (2-3%)

- Not suitable for highly deformable crash structures

- Alternative: Squeeze casting or wrought aluminum alloys

When Steel Outperforms Die Casting

| Application | Reason | Alternative |

| B-pillars | Crash energy absorption | Press-hardened steel |

| Suspension arms | Fatigue resistance | Forged steel |

| Brake components | Thermal stability | Cast iron |

Emerging Solutions

- High-integrity die casting processes (e.g., vacuum-assisted)

- Advanced aluminum alloys with improved ductility

- Part consolidation strategies to offset tooling costs

Why Choose JUFENG Precision as Your Trusted Automotive Casting Manufacturer?

As a leading die casting specialist, JUFENG Precision delivers precision-engineered solutions that meet the exacting standards of modern automotive manufacturers. Our commitment to excellence is reflected in every component we produce.

Key Advantages of JUFENG Automotive Castings:

✔ Material Expertise

- Comprehensive alloy selection (ADC12, A380, A356-T6)

- Custom material formulations for specific applications

- Sustainable recycled aluminum options

✔ Lightweight Engineering

- 40-60% weight reduction vs steel components

- Thin-wall capabilities down to 1.5mm

- IATF 16949-certified production processes

✔ Superior Strength & Durability

- Tensile strength up to 320 MPa

- Heat-treated options for enhanced performance

- Rigorous quality testing (X-ray, CMM)

✔ Precision Manufacturing

- ±0.1mm dimensional accuracy

- Near-net-shape production

- CNC machining integration

Our Automotive Capabilities:

- EV battery housings & motor components

- Structural chassis parts

- Powertrain systems

- Thermal management solutions

Why Global OEMs Trust US:

- 15+ years of automotive die casting experience

- Complete in-house design-to-delivery services

- Cost-optimized production solutions

- Strict compliance with global automotive standards

Request a quote for your next automotive casting project

What Design Possibilities Does JUFENG Offer for Automotive Castings?

At JUFENG, we push the boundaries of automotive die casting with innovative, high-performance solutions tailored to meet the evolving needs of modern vehicles. Our design capabilities combine engineering precision with manufacturing excellence to deliver components that excel in both form and function.

Custom Design Solutions for Automotive Applications

✔ Complex Geometries – Thin-wall designs (as low as 1.5mm) and intricate shapes for lightweight, high-strength components

✔ Integrated Features – Built-in fastening points, cooling channels, and reinforcement ribs to reduce assembly steps

✔ Optimized for Performance – CFD and FEA-validated designs for structural integrity and thermal management

Advanced Manufacturing Techniques

- High-Pressure Die Casting (HPDC) for high-volume precision parts

- Multi-Slide Molding for complex undercuts and tight tolerances (±0.1mm)

Why Choose JUFENG for Your Automotive Casting Designs?

✅ End-to-End Support – From CAD prototyping to mass production

✅ Material Flexibility – Aluminum (ADC12, A380), magnesium, and zinc alloys

✅ EV-Ready Solutions – Battery trays, motor housings, and structural components

✅ IATF 16949 Certified – Ensuring compliance with global automotive standards

Explore the Future of Automotive Casting with JUFENG

Why Aluminum Die Casting is Ideal for Electric Vehicles?

As the automotive industry accelerates its transition to electrification, aluminum die casting has emerged as the manufacturing solution of choice for EV components. At JUFENG, we leverage this advanced technology to deliver optimized solutions that address the unique demands of electric vehicles.

Key Advantages of Aluminum Die Casting for EVs:

✔ Superior Weight Reduction

- 50% lighter than steel components

- Enables 6-8% improvement in battery range per 100kg weight savings

- Ideal for large structural components like battery trays and body frames

✔ Enhanced Thermal Management

- 3x better thermal conductivity than steel (121-151 W/m·K)

- Integrated cooling channel designs for battery thermal regulation

- Improved heat dissipation for power electronics and motors

✔ Optimized Structural Performance

- High strength-to-weight ratio (A356-T6: 310MPa tensile strength)

- Excellent energy absorption for crash safety

- Suitable for critical structural applications like battery enclosures

✔ Unparalleled Design Flexibility

- Enables part consolidation (reducing assembly by 30-50%)

- Complex geometries with wall thicknesses down to 1.5mm

- Net-shape forming minimizes secondary machining

✔ Sustainable Manufacturing

- 95% material utilization rate

- Closed-loop recycling capability

- Lower carbon footprint compared to steel alternatives

EV-Specific Applications:

-Structural battery housings

- Electric motor components

- Power electronics enclosures

- Chassis and suspension parts

At JUFENG, our IATF 16949-certified facilities specialize in high-performance aluminum die casting solutions tailored for next-generation EVs.

Which Quality Standards Are Followed by JUFENG to Produce Automotive Castings?

For decades, JUFENG has established itself as a trusted partner in the die-casting industry, combining technical expertise with innovative manufacturing solutions. Our commitment extends beyond meeting current automotive casting requirements – we actively collaborate with suppliers to develop customized solutions for tomorrow’s challenges.

At the core of our operations lies an uncompromising adherence to international quality benchmarks, implemented through rigorous processes and a culture of excellence among our professional teams. This dedication to quality is validated by our prestigious certifications:

ISO 9001 Certification

As the globally recognized standard for quality management systems, ISO 9001:2015 guides JUFENG’s processes to consistently meet and exceed customer expectations. For our automotive die-casting operations, this means:

- Implementing robust quality control measures at every production stage

- Maintaining traceability throughout our manufacturing process

- Continuously improving our aluminum and zinc die-casting techniques

- Ensuring all automotive components meet precise dimensional tolerances

Our ISO-certified system integrates quality assurance into every aspect of operations – from molten metal treatment to final machining – guaranteeing premium castings for global automotive applications.

IATF 16949 Certification

This technical specification represents the gold standard for automotive quality management systems. JUFENG’s IATF certification demonstrates our capability to:

- Meet stringent automotive industry requirements for die-cast components

- Implement advanced process control in high-pressure die casting

- Maintain exceptional surface finish and mechanical properties

- Achieve consistent part-to-part repeatability for high-volume production

Aligned with our vision of excellence, IATF 16949 reinforces our commitment to:

- Continuous R&D in alloy development and casting technologies

- Proactive defect prevention through statistical process control

- Optimization of material usage and reduction of production waste

- Supply chain management for automotive-grade materials

As an extension of our ISO 9001 system, this certification ensures JUFENG remains at the forefront of automotive die-casting innovation while delivering components that meet the most demanding OEM specifications.

How to Implement the QA Measurements in Medical Casting?

In medical die casting, quality is non-negotiable. Every component—whether for surgical tools, implantable devices, or diagnostic equipment—must meet stringent industry standards to ensure patient safety and device reliability. To achieve this, manufacturers must implement rigorous Quality Assurance (QA) measurements throughout the production process.

- Precision Measurement & Inspection Equipment

Medical die casting demands ultra-tight tolerances and flawless surface finishes. To verify part accuracy, manufacturers use:

- CMM (Coordinate Measuring Machines) – For 3D dimensional analysis

- Optical Comparators & Laser Scanners – For high-resolution surface inspection

- X-ray & CT Scanning – To detect internal defects in critical components

- Strict Process Control & Documentation

- Real-Time Process Monitoring – Sensors track pressure, temperature, and cycle times to ensure consistency.

- Statistical Process Control (SPC) – Data-driven adjustments prevent deviations before defects occur.

- Full Traceability – Each batch is logged with material certifications, machine settings, and inspection reports.

- Validation & Compliance Testing

Medical castings must comply with ISO 13485, FDA, and ASTM standards. Key tests include:

- Dimensional & Mechanical Testing (tensile strength, hardness)

- Leak & Pressure Testing (for fluid-handling components)

- Biocompatibility Checks (for implantable parts)

- Skilled QA Personnel & Continuous Improvement

Even with automation, human expertise ensures final validation. QA teams perform:

- First-Article Inspections (FAI) – Before mass production

- Random Sampling & AQL Checks – During production

- Root Cause Analysis (RCA) – For any non-conformities